Cruise Actuator Fix Part 1

EDIT 10-18-2015 Now applicable for all Previas, NON-SC and SC

If your cruise acts like mine did, then you should read on. Fixing it may be as simple as replacing the motor brushes.

Mine engaged for a time (split second to minutes) then dropped out as the actuator magnetic clutch released, and the Cruise dash lamp flashed slowly 5 times. At first, it only did it sometimes, but it got worse for a couple of years until it would not stay on at all. If your’s does this, then there is a good chance the fault is NOT in the many other possible components of the Cruise system. If it doesn’t engage but flashes 5 times, it still might be the actuator brushes, but there may be other problems not covered here.

If you have the engage/drop out/5 flashes, I suggest you:

(This Post, Part 1)

1. Read Codes

2. If you have code 11 and/or 13, Remove Actuator

3. Clean Cable

4. Bench Test Actuator

(Next Post, Part 2)

5. If Actuator has the bad brushes signature from your testing, Replace Actuator Brushes

6. Reinstall, Clear Codes, Road Test, Fixed?

I’ll take these one at a time after covering general info

GENERAL:

The actuator is under the dash above the accelerator pedal and is nearly identical for SC and NON-SC Previas. I have tested both. The mounting is the same but the electrical connector and lever arm length is different. This may be due to the increased load of 3 throttle cables in the SC instead of 2 in NON-SC Previa.

The SC actuator's part number is 88002-28080. This is currently specified for ALL SC models from 94 to 97. The list below is what is specified as replacement parts.

88002-28080 Specified for all 96 and 97 (all models are SC)

88002-28080 Specified for all 94 and 95 SC

88002-28071 Specified for all 94 and 95 non-SC

88002-28070 Specified for all 93 (all models are non-SC)

88002-28050 Specified for all 91 and 92 (all models are non-SC)

The Cruise module (also called the cruise ECU or computer) that runs the actuator also changes but not necessarily with the actuator, indicating to me that the actuators are very similar. So sticking to the actuator specified for your Previa is safe but may not be necessary. However the lever arm change from non-SC to SC surely is. The major change was from non-SC to SC. The other changes may just represent improvements if the connectors are the same. So my guess is, if the actuator’s connector fits, it should probably work.

Cruise ECUs

88240-28170 Specified for all 97 (all models are SC)

88240-28160 Specified for all 96 (all models are SC)

88240-28160 Specified for all 94 and 95 SC

88240-28150 Specified for all 94 and 95 non-SC

88240-28131 Specified for all 92 and 93 (all models are non-SC)

88240-28101 Specified for all 91 (all models are non-SC)

I know that other part numbers were delivered on vehicles, but they were superceded.

The cruise ECU has overload protection and performs fault detection. It will record codes and shut down Cruise if something is not right. I have never had a problem with one, so don’t suspect it at first.

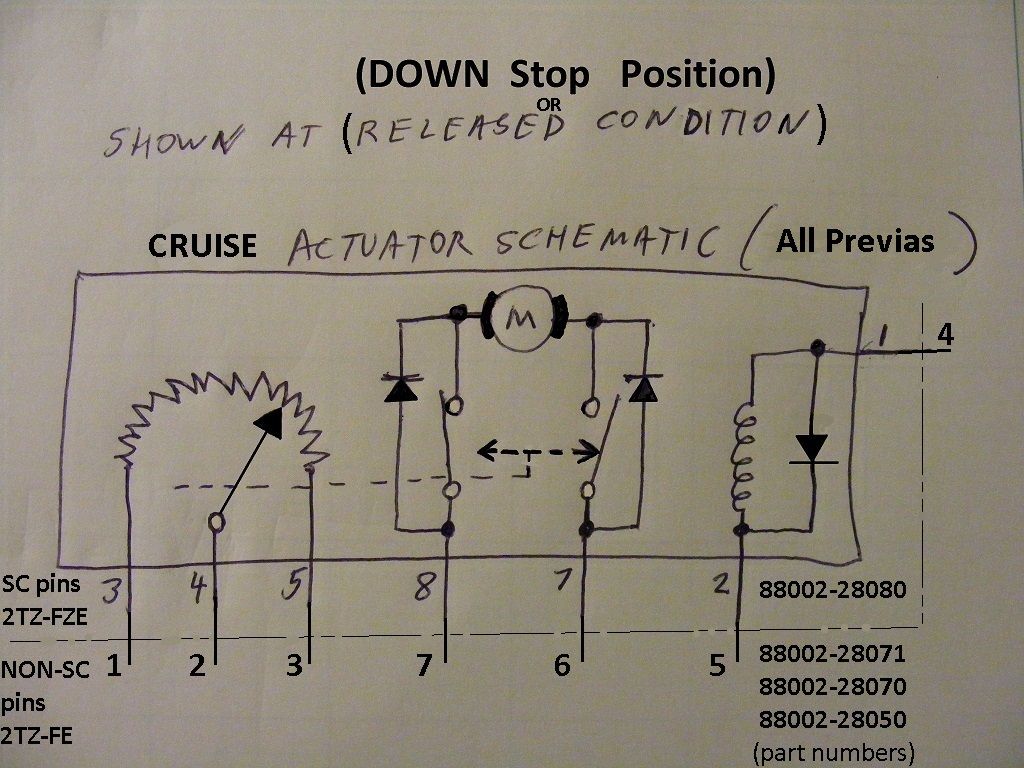

I have tested both types of actuators (91, 94, 95 and 96, and the electrical connector has the same functions thru it, but the connector is a different shape. All the actuators work by the same method with the same tests and measurements, and the connector pins numbers and locations used for these tests are the only thing that changes. There are three separate electrical circuits in the actuators:

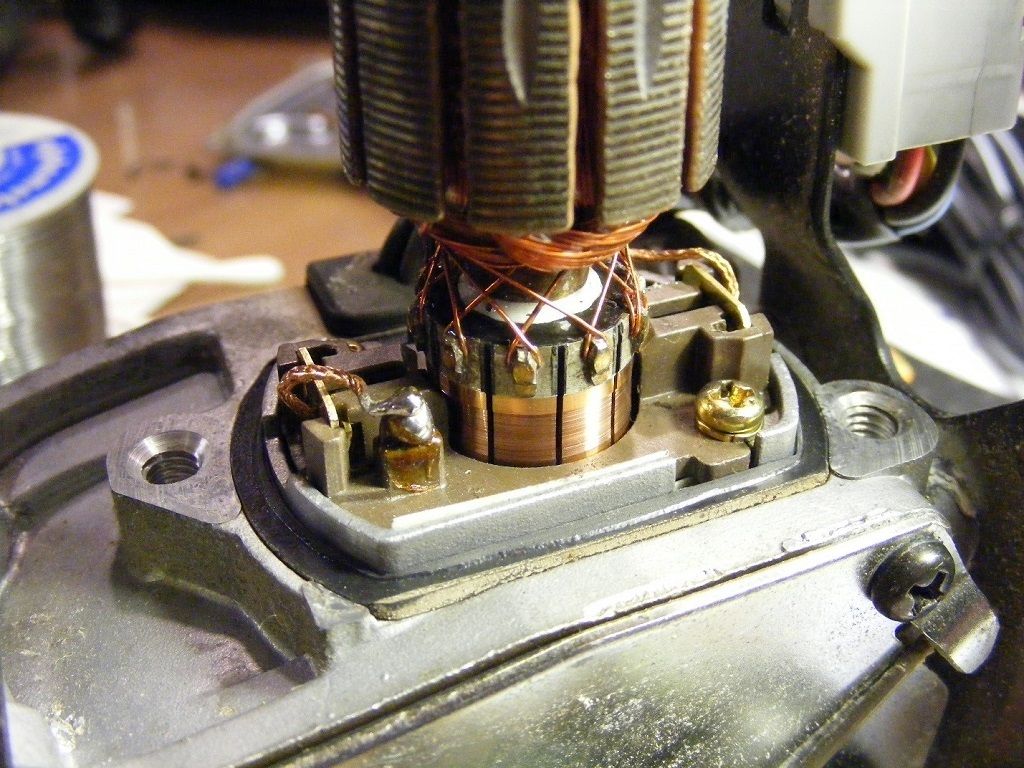

The motor - A two wire permanent magnet motor that is driven both directions by the full bridge driver in the Cruise ECU box. Its output shaft is a worm gear and is part of the armature. It can drive the throttle down and up with great authority and moves the output arm from stop to stop in about a second. It can break fingers, so just because it is quiet, don’t underestimate its power.

The position sensor – This is a three wire potentiometer (~2k ohm variable resistor) that is gear driven and linked to the output lever arm. It is a voltage divider that tells the Cruise ECU where the lever arm is at all times. And when Cruise is engaged, it also is an indicator of the accelerator pedal position.

The magnetic clutch – This is a two wire solenoid type device in the actuator that mechanically links the motor/gear train to the output shaft/lever arm. It is normally off and the lever arm can be moved freely stop to stop. When powered by the Cruise ECU with 12 volts, it draws about as much current as a typical auto relay (~300 mA) and is on whenever Cruise is set. Its release can be heard whenever the Cruise is disengaged. The lever arm is spring loaded and snaps back away from pushing the accelerator pedal.

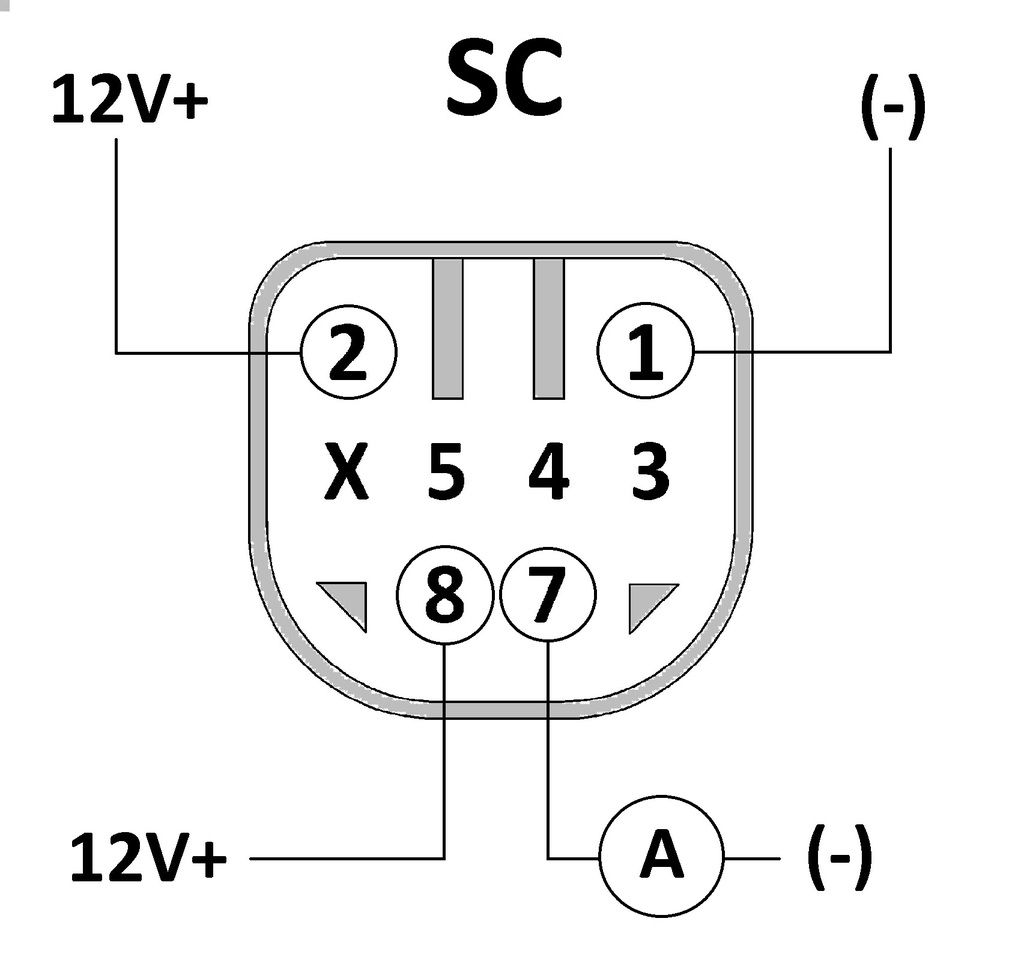

There are 7 pins in the connector for these seven wires. The NON-SC connector is a 7 pin connector with pins 1-7. The SC connector is an 8 pin connector with no pin in the

#6 position.

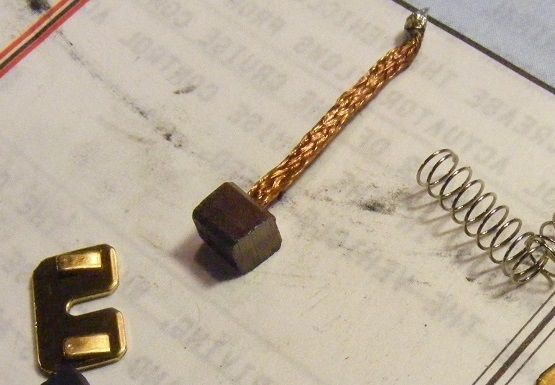

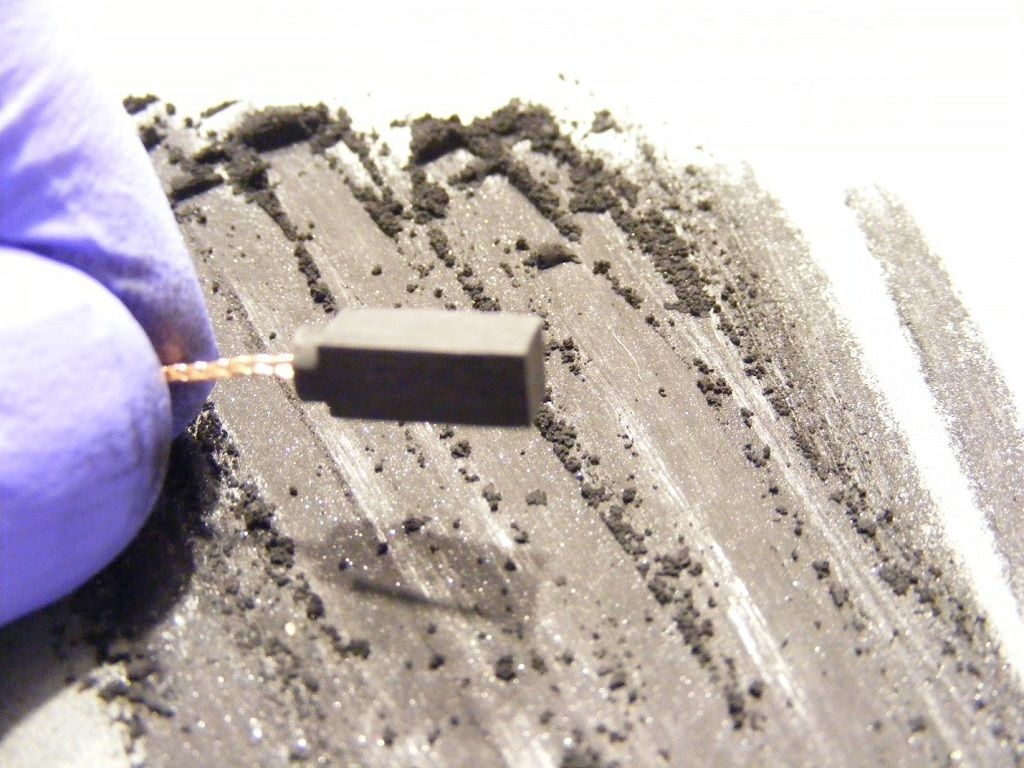

If the Cruise was used heavily for its life, the brushes will probably go bad before anything else fails. It is a very tough and well-built actuator and so goes the price.

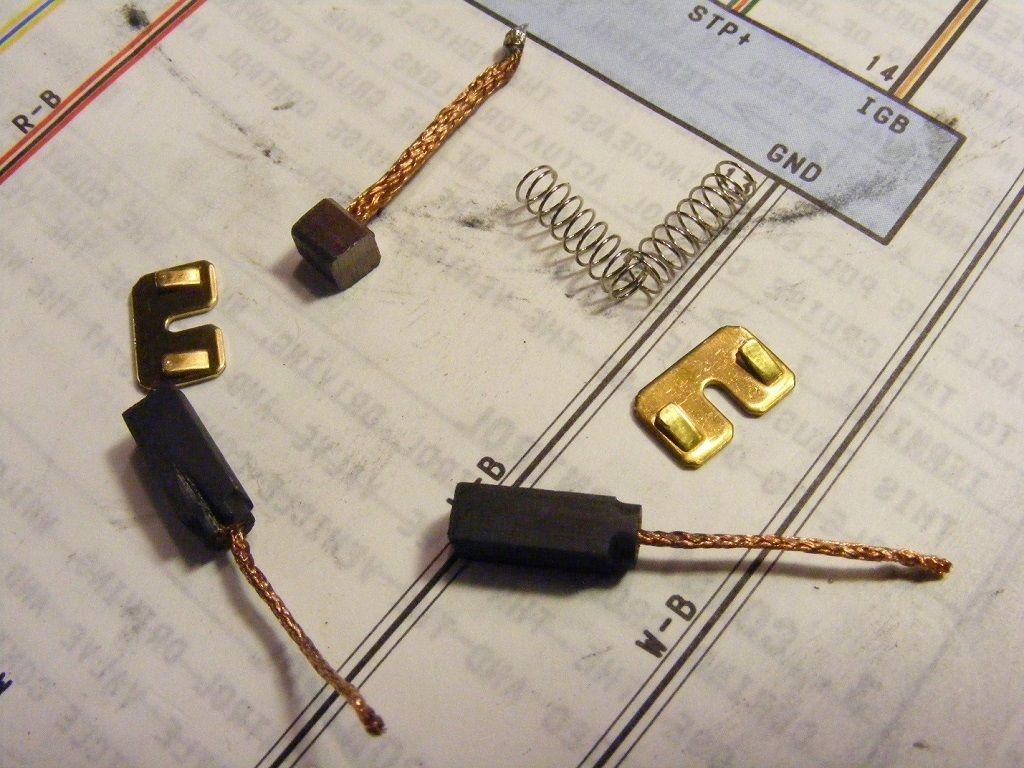

The brushes will eventually wear down to nubs. Their wear rate will be accelerated as load increases. (That’s why cleaning the goo out of the throttle cable is a good idea). Mileage is not necessarily a gage of how long they last. My 96 previa started giving problems at about 130k miles, probably because I use it a lot. But my 95 previa started to give problems at about 180k. I found and fixed the cable (Goo) problem below and that seemed to fix it until it started dropping out just now at 210k miles. Cable cleaning did not give me any reprieve with the 96 probably because the brushes were so far gone. Here is what a worn out brush from my 96 SC looks like.

1. READ THE PROBLEM CODES:

The code reading procedure is similar for the SC and the non-SC Previas. I recommend a fresh read of the codes. The CC ECU circuits were improved between the 91 and the later SC Previas. With the 91, problem codes were only retained in the ECU as long as the ignition remained on. Once the ignition is turned off, the problem codes are lost. With the SC Previas, the problem codes are retained in the CC ECU with ignition off and are cleared by pulling the ECU-B fuse for 10 or more seconds with the ignition off. I do not know if the procedure changed with the later NON-SC Previas, but the important thing to note here is that the codes you will see if your brushes are bad will be the same for all models.

To get a fresh read of the codes, the car must be drivable.

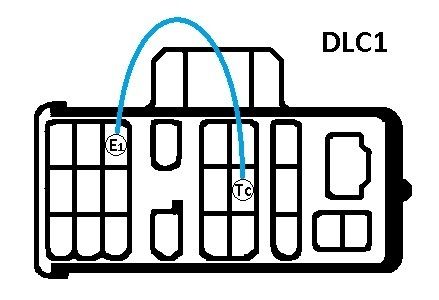

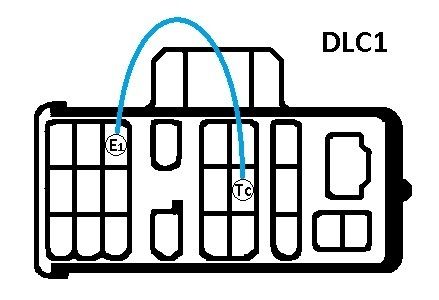

For the SC Previas, reset the codes with the ignition off by pulling the ECU-B fuse for 10 seconds with the ignition off, then drive the car and use the Cruise until it drops out. You can stop the car and read the codes then or shut it down and do it later. To read the codes, turn the ignition on and with a piece of wire, connect E1 and Tc in the DLC1 connector under the driver seat (see drawing). The problem codes will then flash out on the Cruise lamp in the instrument cluster.

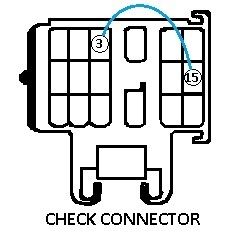

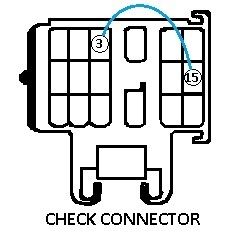

For the 91 Previas,(and maybe the rest of the NON-SC Previas, check your shop manual), drive the car and use the Cruise until it drops out. Bring the car to a stop, but don’t turn off the ignition. To read the codes, use a piece of wire the same as for the SC Previas and connect the same two terminals in the connector under the driver seat (see drawing). The pin arrangement is almost identical but the connector is called the “check connector” instead of the DLC1. The pins are in the same place and are called pins 3 and 15 instead of E1 and Tc. The problem codes will then flash out on the Cruise lamp in the instrument cluster the same as for the SC Previas.

If everything is normal (no problem codes) you get continuous short flashes (about 2/second)

If you have problem codes, then as long as the ignition remains on and the jumper in, all codes will read out from lowest to highest and repeat over and over. (example 11,13, ___ 11, 13, ___11, 13,___...and so on)

All codes are 2 digits

All the possible codes in my 95 and 96 manuals are the same (11, 12, 13, 21, 23, 32, 34, and 41). The codes for the 91 are almost the same (11, 12, 13, 21, 23, 31, 33, and 41), but the same codes (11 and 13) are likely to read out for worn out brushes. Each code means something different and you may have any number of codes read out.

Timing of the flashes will be like this (if this doesn’t make sense to you, maybe the examples below will):

Jumper wire connected, (4 sec wait), FIRST CODE, (2.5 sec wait), SECOND CODE, (2.5 sec wait), THIRD CODE…until all codes are read then repeat. There will be 1.5 seconds between the two digits in a CODE, the number of flashes for each digit will come at a rate of 1 per second and each flash is about 0.5 seconds long

Example of what codes 11 and 13 will look like (Below, each character represents 0.5 seconds, “-“ means cruise lamp is off and “0” means lamp is on):

Connect the jumper

--------0---0-----0---0-0-0--------0---0-----0---0-0-0--------0---0-----0---0-0-0 and so on

This is interpreted as:

______1__1___1__3_________1__1___1__3_________1__1___1__3__

Another example for code 41 (cruise ECU malfunction):

--------0-0-0-0---0--------0-0-0-0---0--------0-0-0-0---0 and so on

Interpreted as:

_________4____1________4____1________4____1_

Another example of codes 32 and 34

--------0-0-0---0-0--------0-0-0---0-0-0-0--------0-0-0---0-0--------0-0-0---0-0-0-0 and so on

Interpreted as:

________3____2________3______4__________3____2________3______4__

My 96 output the first example above, codes 11 (excessive current flowed to motor drive circuit) and 13 (Position sensor circuit abnormal or Open circuit in motor). If you get either one of these, I would next pull the actuator for a bench test.

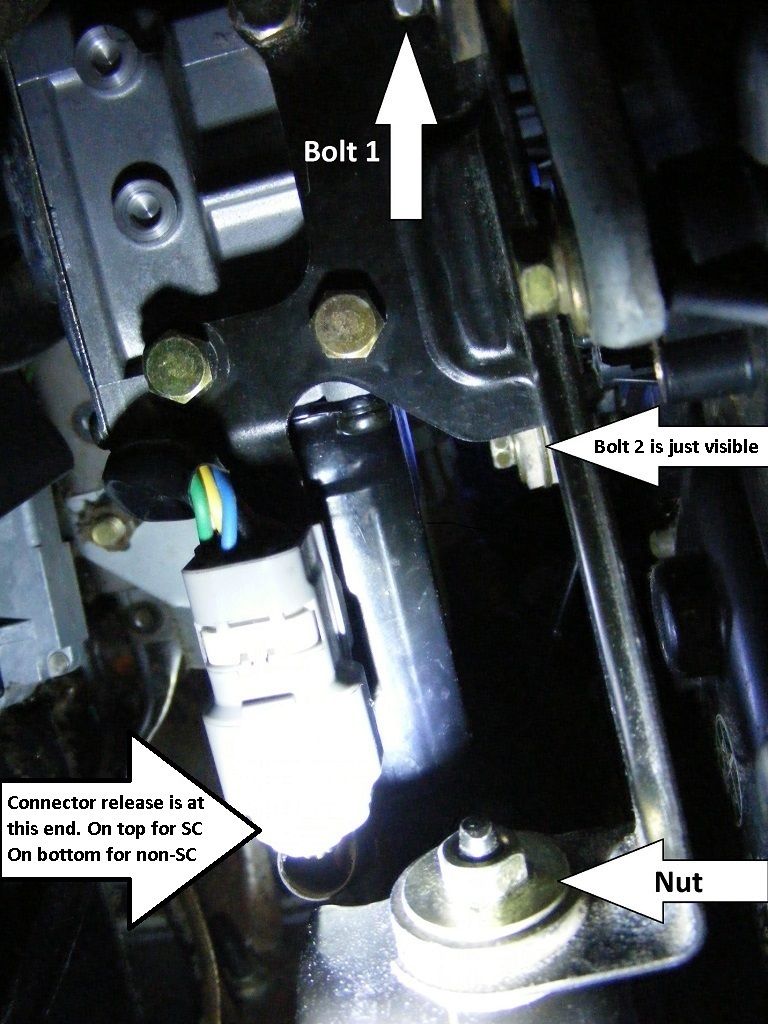

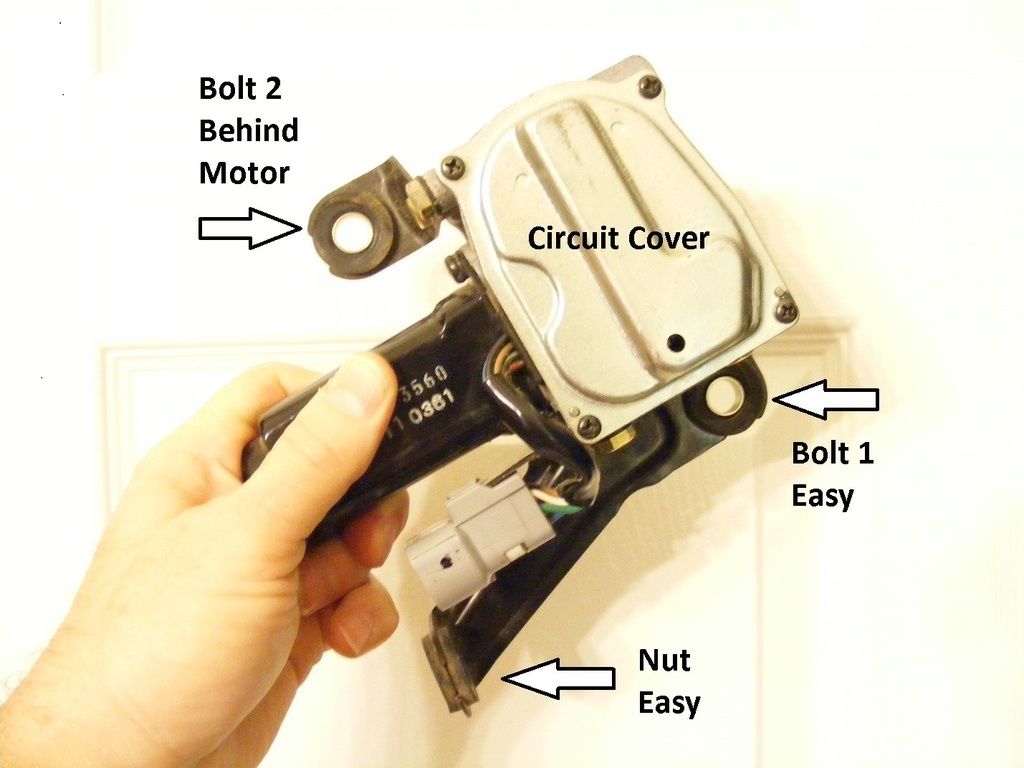

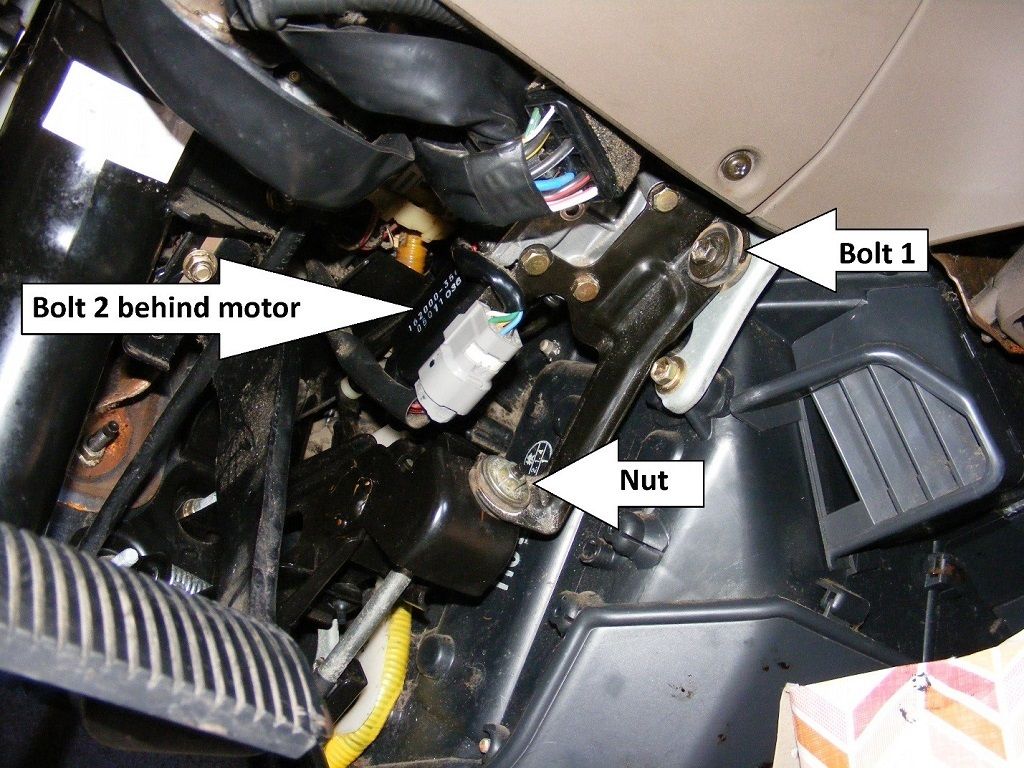

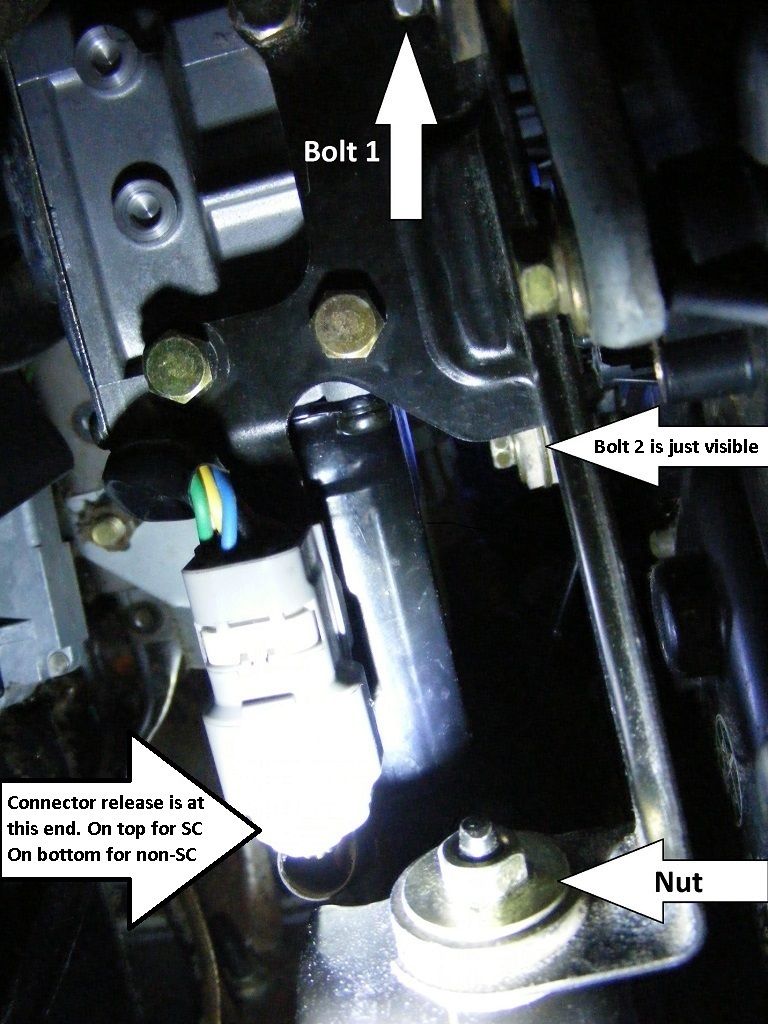

2. REMOVE ACTUATOR

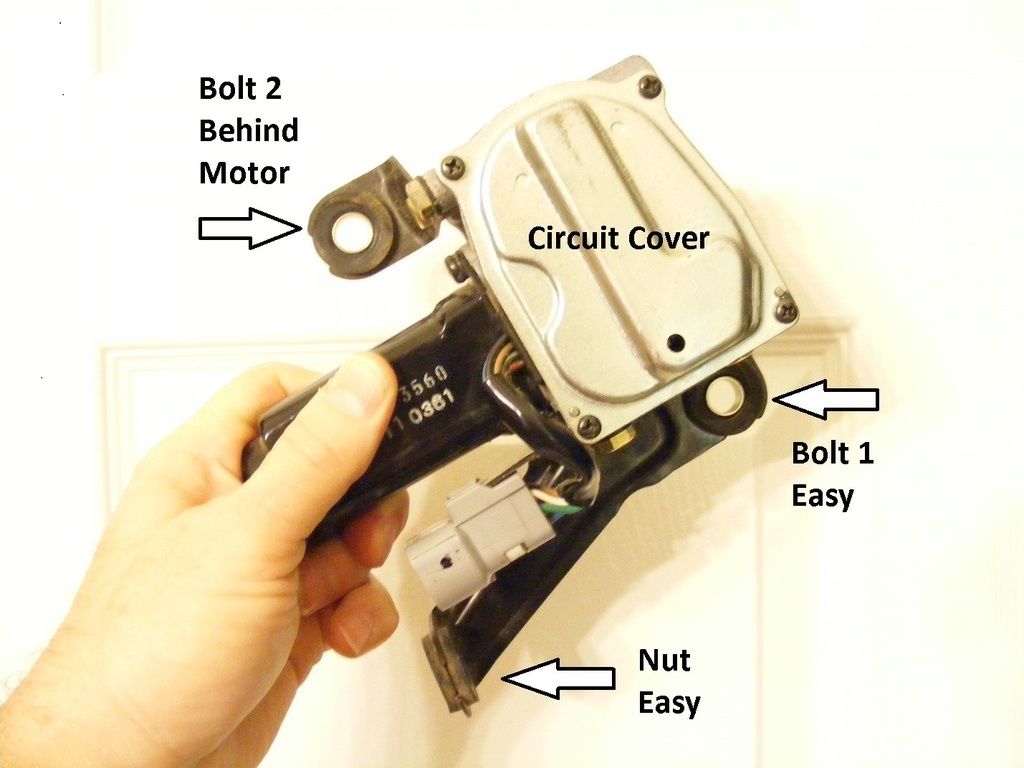

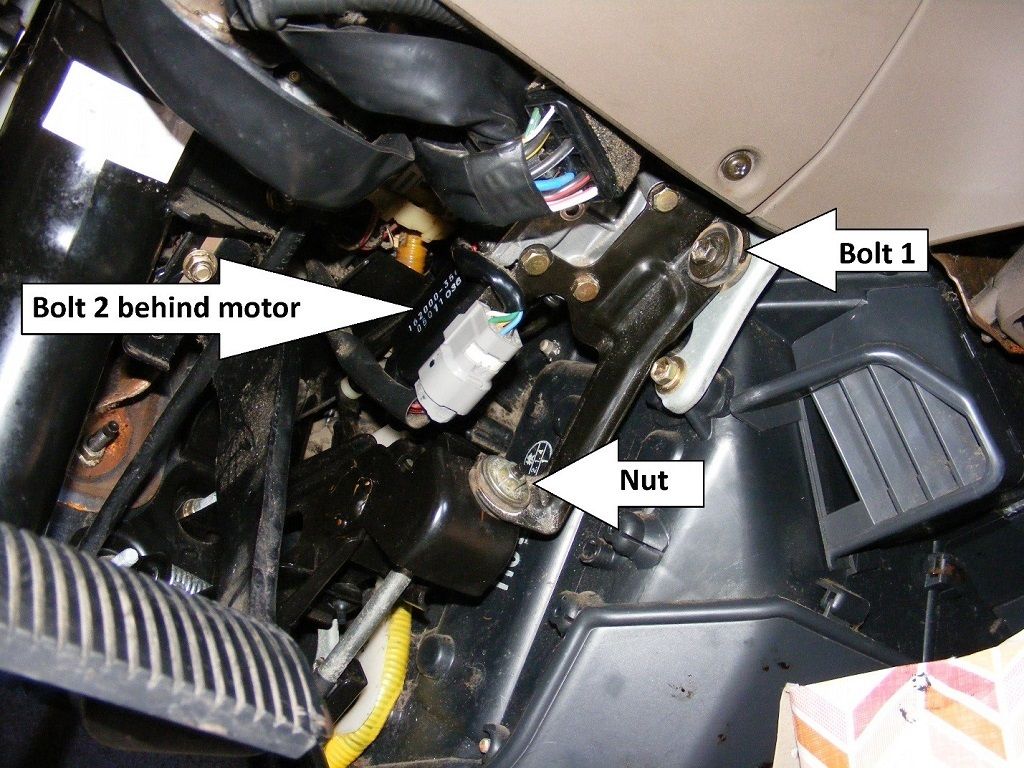

The actuator is held in by two identical bolts and one nut and is pretty easy to remove. I don’t find it necessary to disconnect the battery, but you can do so if you like.

Unplug the electrical connector. The connector release squeeze part is on the wire harness side on the top of the wiring harness connector (motor side) for the SC and on the bottom of the connector for the NON-SC Previas. I also try to show the connector release location two pictures down.

Reach bolt 2 with an extension of the right size (I seem to remember 2-3 inches) and ¼” drive. Maybe play around with a deep socket as well.

Once connector, bolts and nut are out, you can lift the cruise off of the nut’s stud and it will drop down. Gently rotate it, while not binding the link rod and ball socket, to the position shown.

Using a small screw driver, pry the link rod off the ball. The spring clip on the link rod will let the ball free with fairly light force, so don’t force it if you are not on it right. Pry between the link rod end and the lever arm, as I tried to show here on my back with a camera and flashlight in my face.

Once it pops off, the actuator drops in your hand. Now take it to your electrical bench (or kitchen table).

One word of warning, the link cable is now just dangling. I would not and did not drive the car like this. I just left it until I had repaired and reinstalled the actuator. If you need to drive while the actuator is out, you should probably unhook the link rod from the other end and remove it so it can’t bind up your accelerator.

3. CLEAN CABLE

This can be done easiest anytime while the actuator is out Your arrangement may be different for NON-SC.I inspected all three cables in my SC. I only found a problem with the cable that goes from the accelerator pedal thru the floor board to the intake manifold block under the driver seat. This goo in the picture was once a small rubber dust boot where the cable comes out of the sheath. It has turned to goo on both my 95 and 96 previas and been pulled into the cable by cable motion. It adds drag to the accelerator movement. While you may not notice it much with your foot, it is significant to the cruise actuator. To clean it you must remove this cable from the car, which is not too hard.

Removing your cable may be a little different on NON-SC Previas.

I removed the accelerator pedal bracket which you see in this picture because I was inspecting everything, but you may be able to pull this cable out without doing that. Peel back the carpet (there is Velcro behind the steering column) to reveal the floorboard grommet bracket. In my 96 Previa, I also had to remove the floor console to get access and free up the carpet (more Velcro). The floor console was not in my 91 Previa. Remove the two bolts holding the cable floor bracket grommet and unclip the cable from a spring clip under the car. Unhook and unbolt the intake block end of the cable. I marked the position of the set nut on that cable end so I could put it back where it was.later. Unhook it from the accelerator pedal bracket and pull it out from inside the car. Once out, the only solvent I found that would cut the goo without damaging the cable is lacquer thinner. Put on some nitrile medical gloves. Apply lacquer thinner to the cable, move it in and out a bunch of times and try to work the lacquer thinner into the cable to dissolve the goo. Wipe the softened goo off the cable, and repeat until you are happy with it. I’m guessing I did it more than 20 times. Several times I used compressed air at the other end to try to blow anything I could out of the cable. I then applied a light plastic-compatible grease to the cable and worked it in. Then reinstalled it. With NO BOOT this time.

4. BENCH TEST ACTUATOR

First just move the ouput lever arm stop to stop. It should move freely and when released, snap back to the idle end (DOWN Stop).

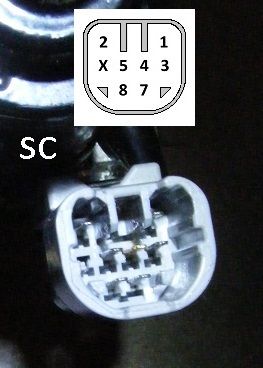

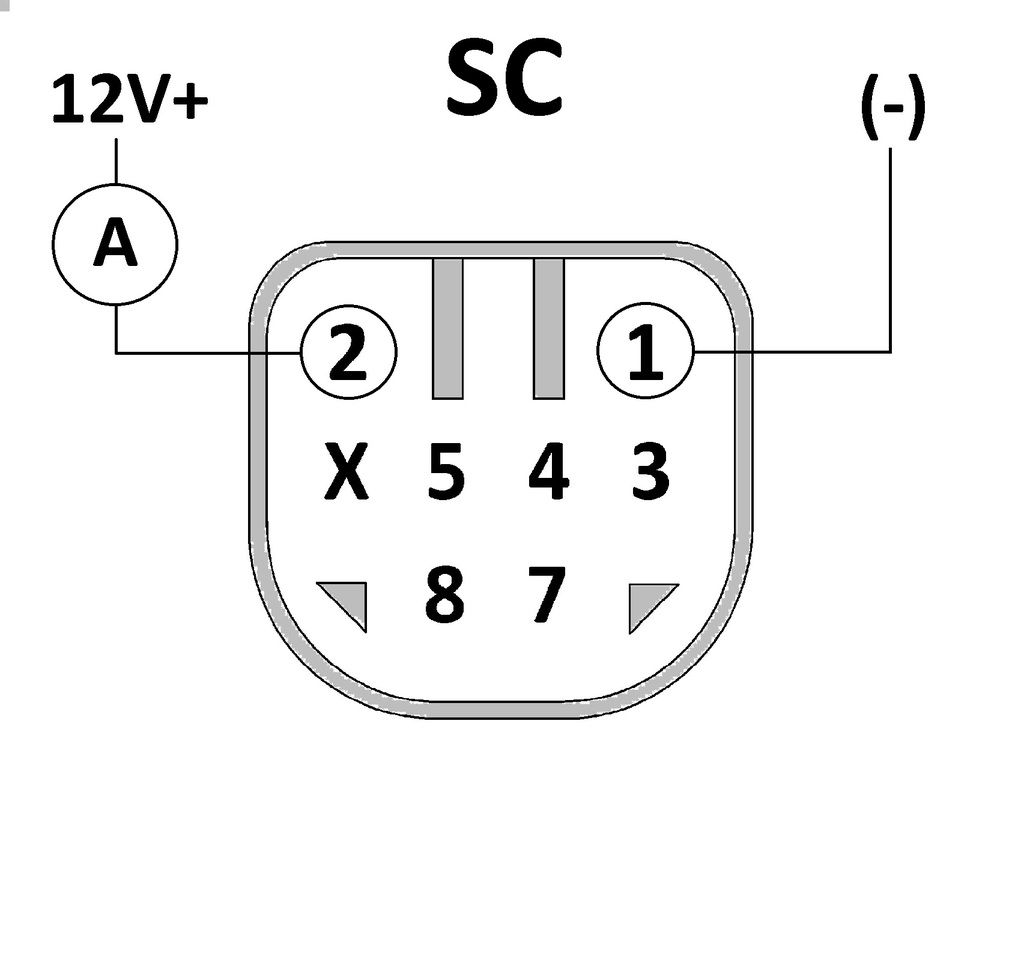

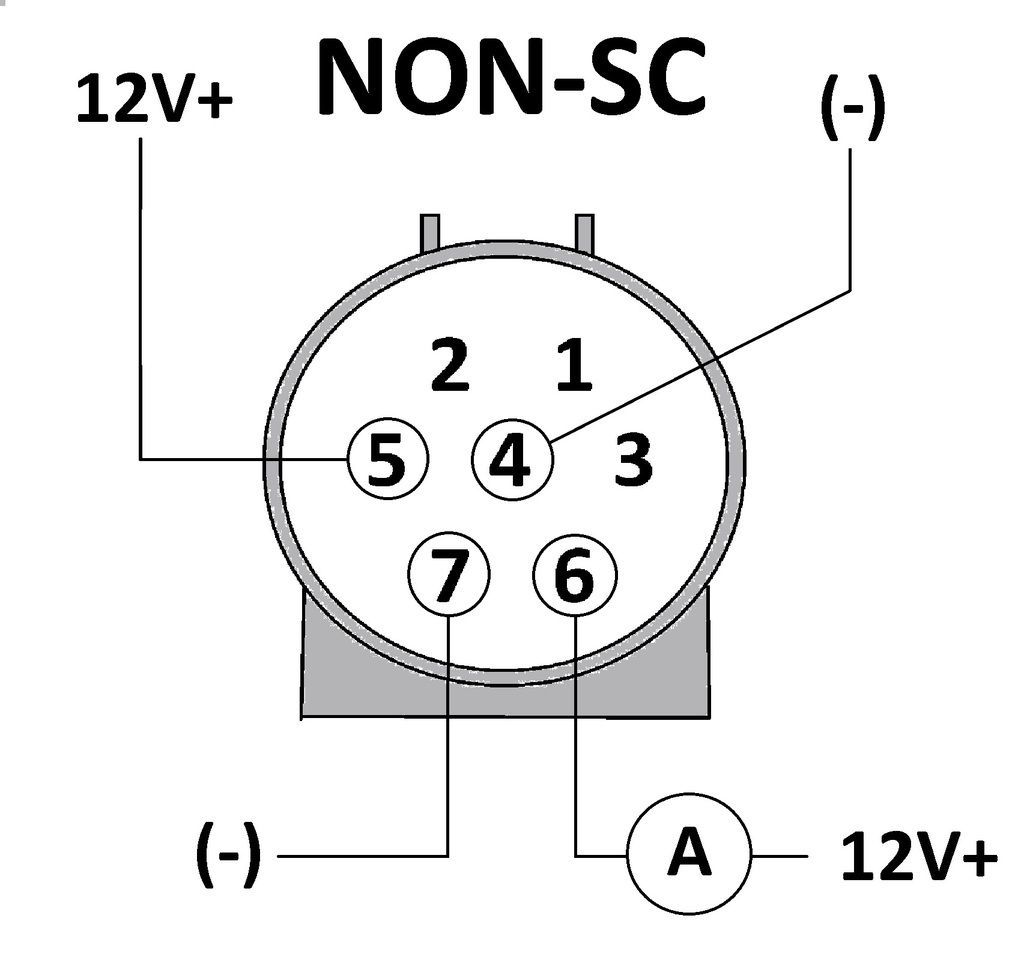

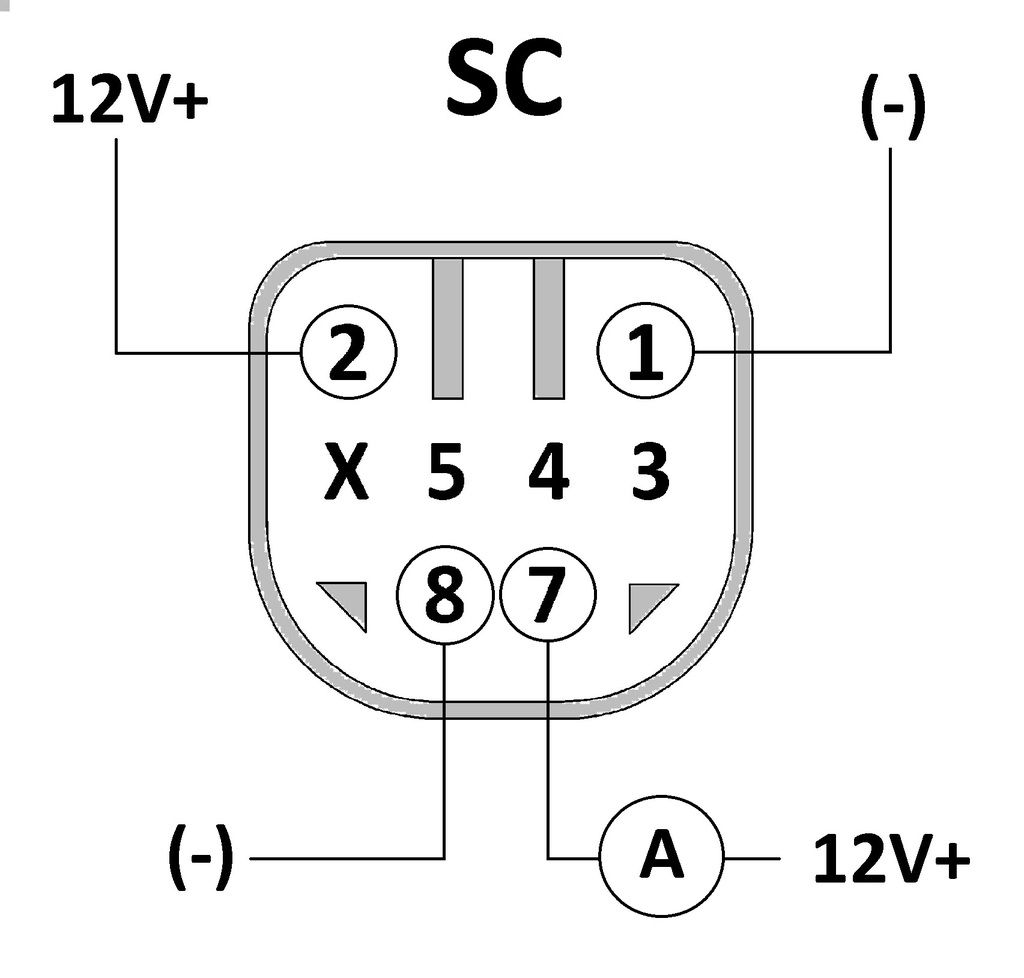

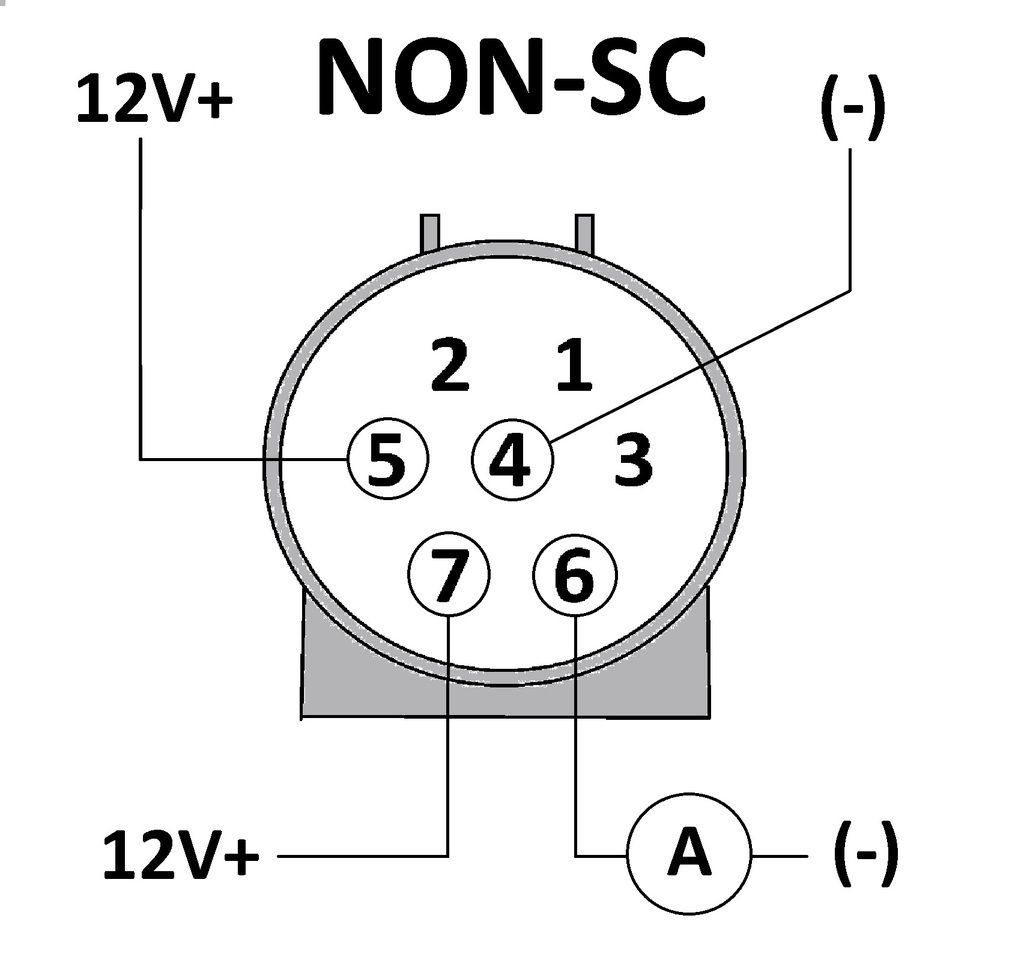

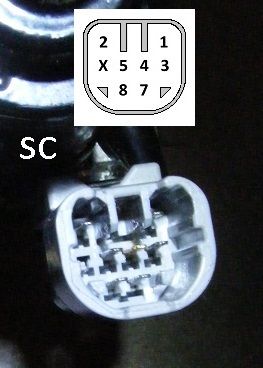

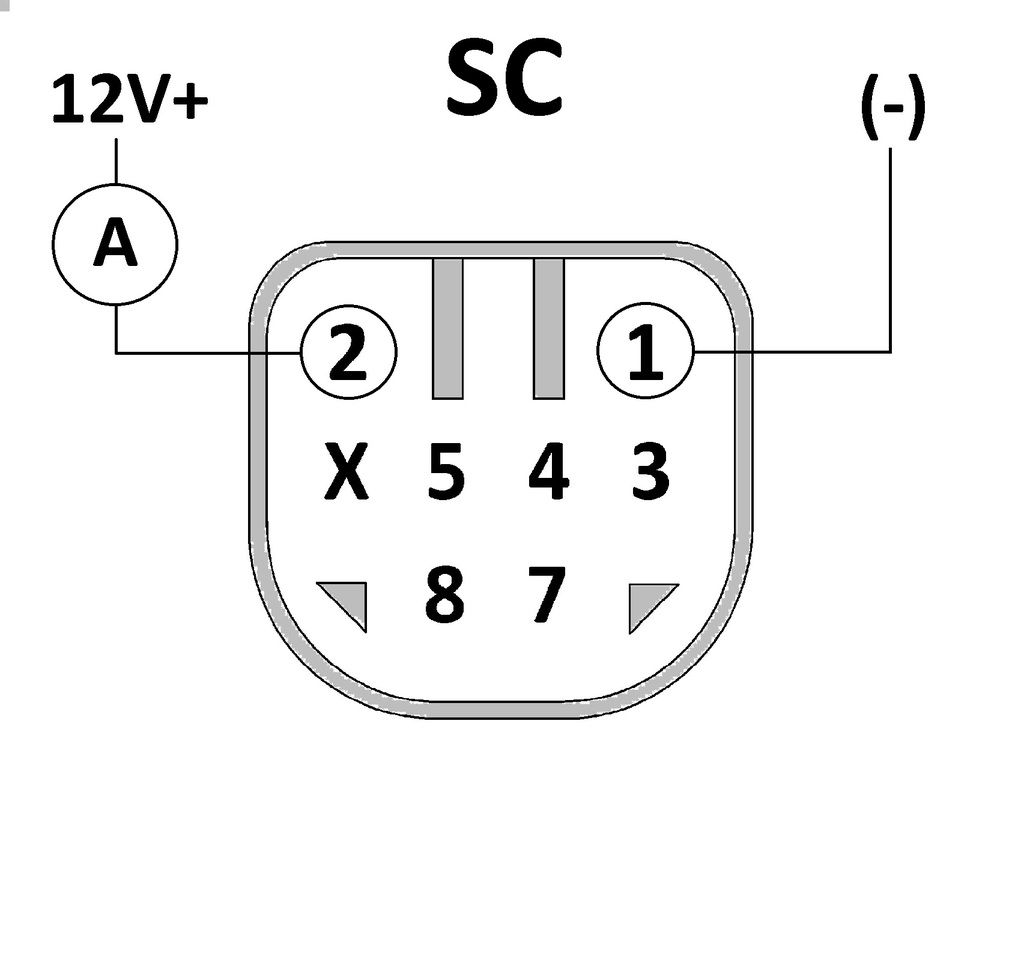

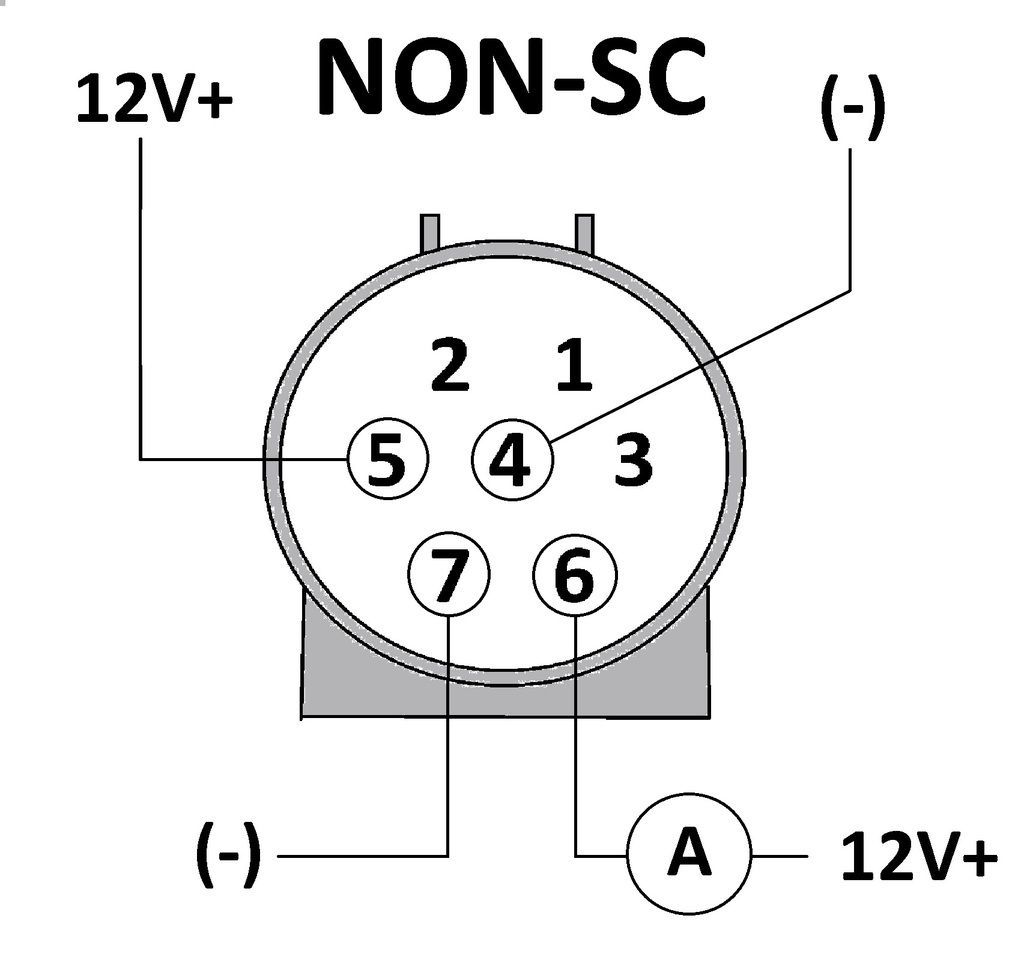

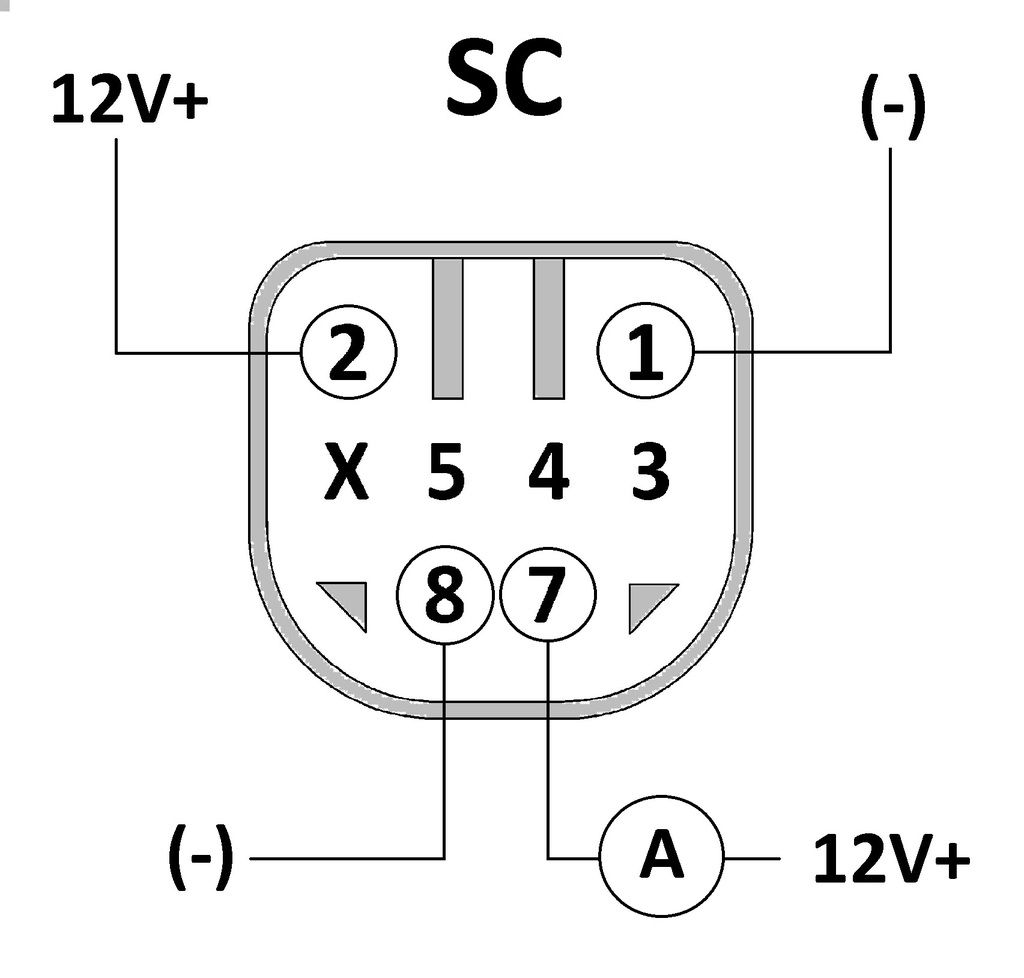

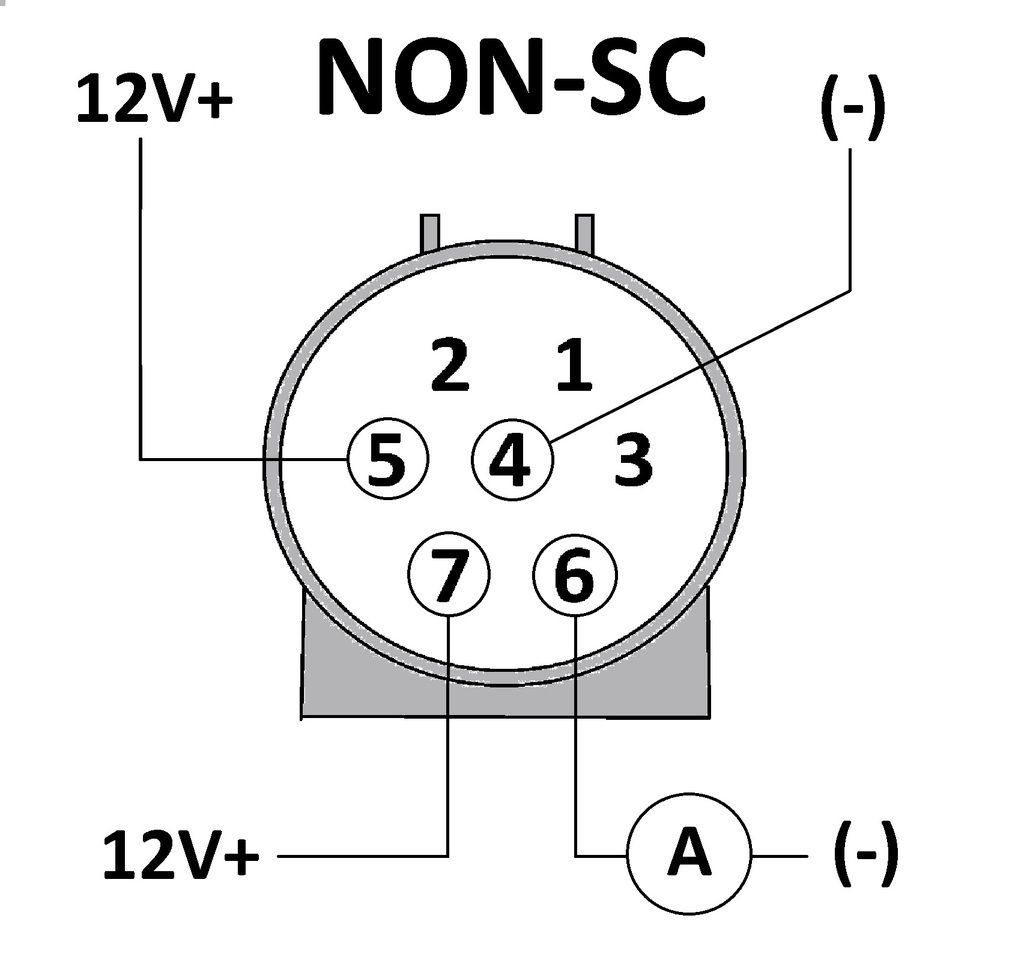

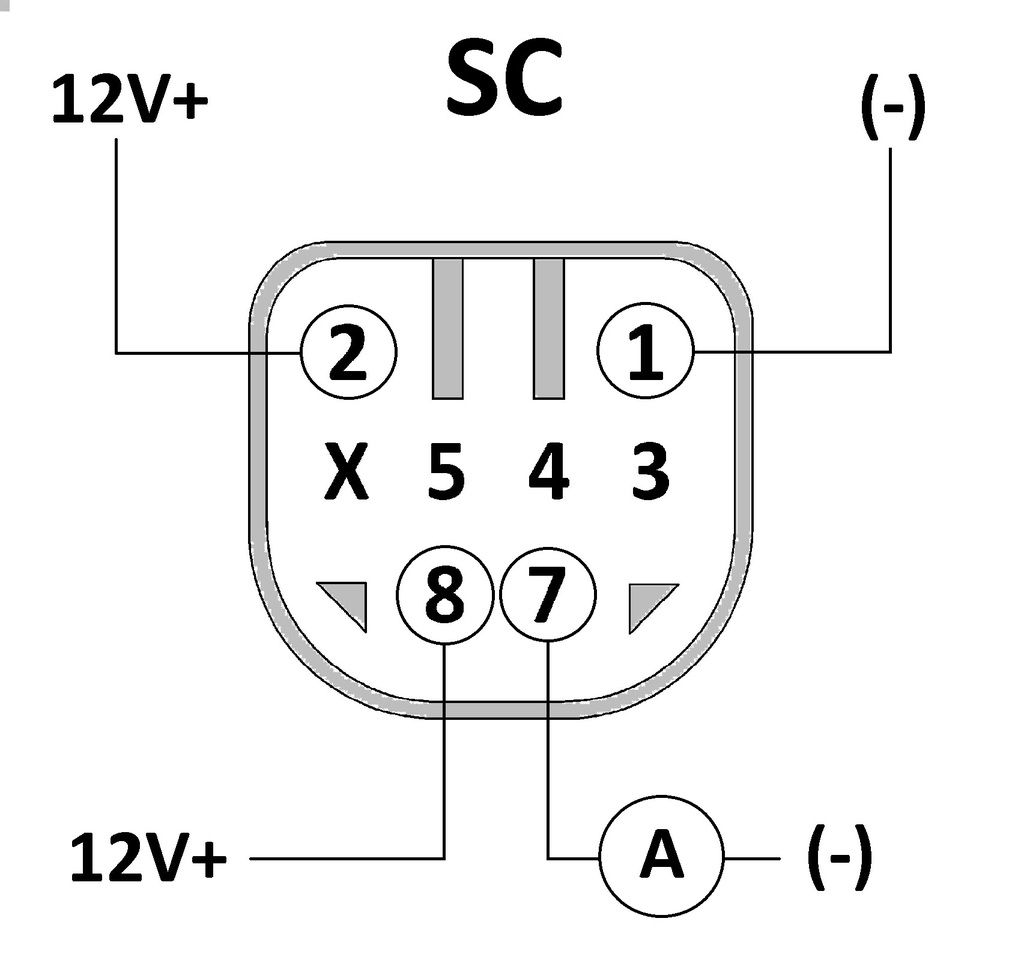

The SC and NON-SC connectors are shaped different. The pin assignments are different as well. The NON-SC connectors have pins numbered 1 thru 7. The SC connector is an 8 pin connector with no pin in position 6.

Warning: There are some errors in the Toyota schematics and shop manuals with respect to the cruise actuator. I will cover this in a separate post. My 1995 and 1996 Toyota shop manuals call for testing the wrong pins. Testing with battery power as instructed must have the correct pin outs or things can fry! There are also errors in the 1995 and 1996 electrical diagram manuals. So my advice is to be very cautious.

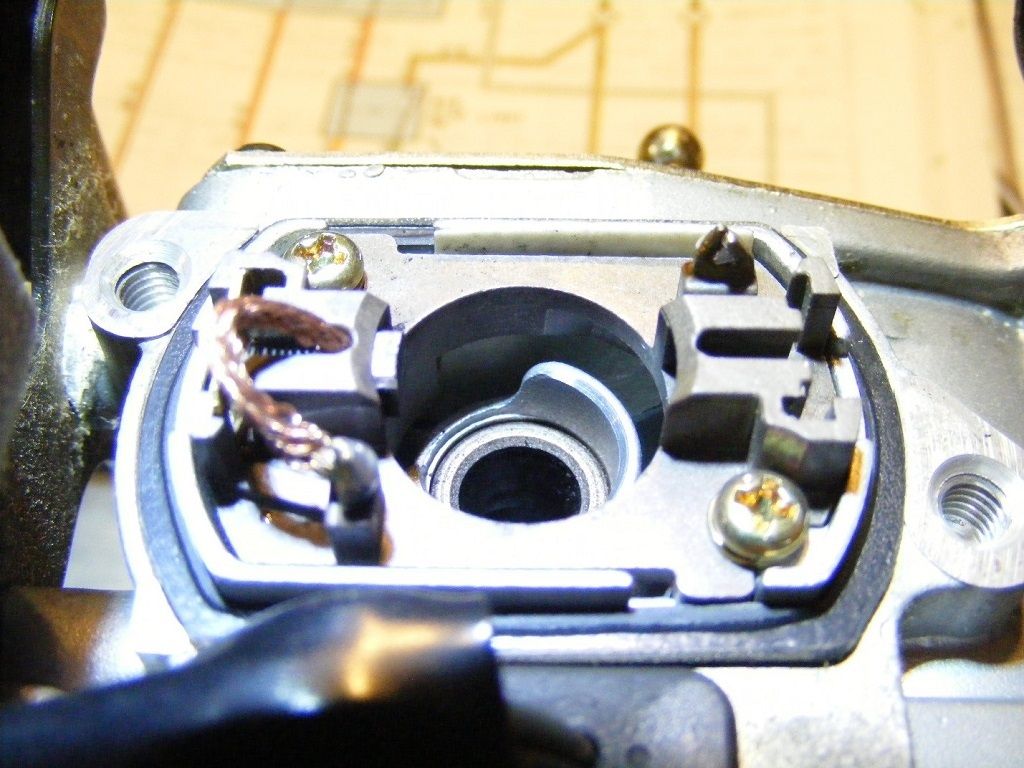

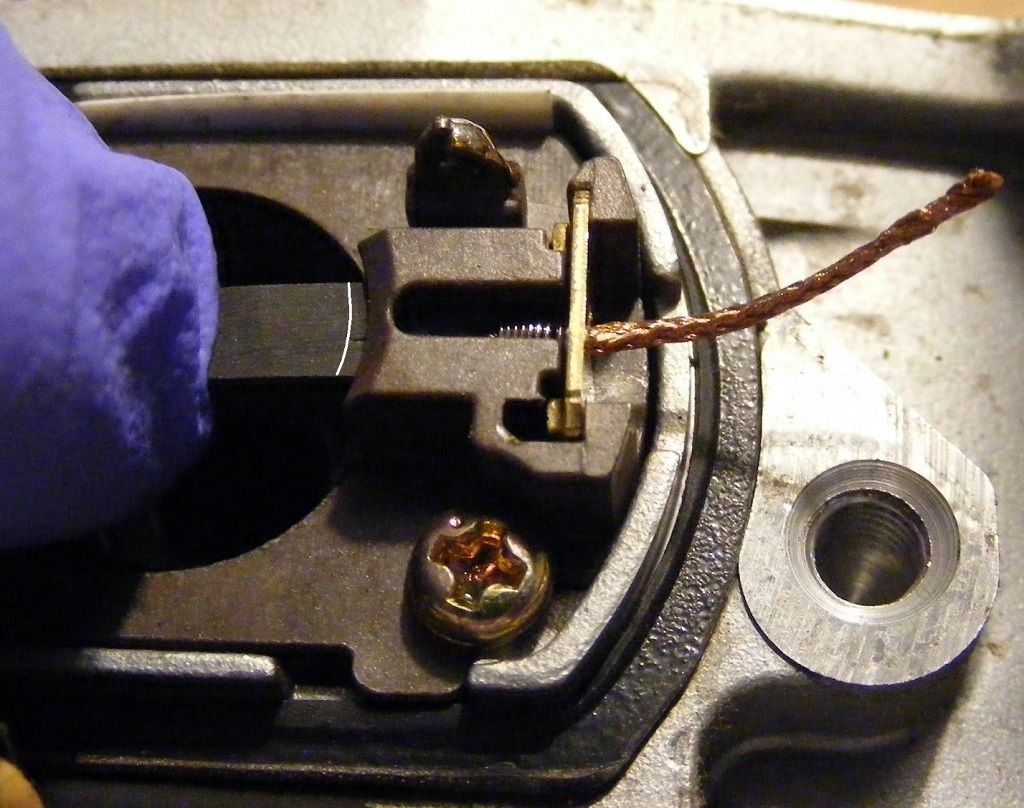

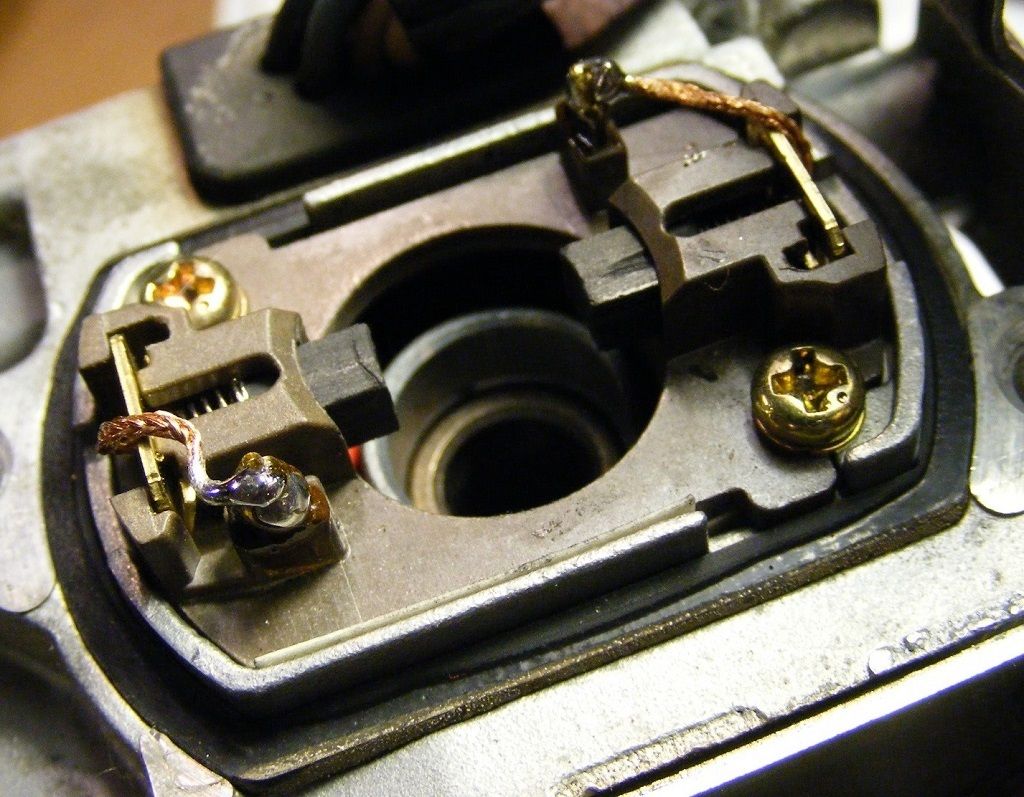

If you are curious or want to trace wires yourself, or want to test and inspect the limit switches or diodes directly, you can pull the electrical cover from the side of the actuator. Nothing will fly out at you. It is a vented panel held with 4 screws and not sealed. However, I would not pull the lever arm panel on the other side as things could spring out at you. Besides, If anything is bad in that side of the actuator, then I would consider the actuator a loss.

The SC Actuator connector pin arrangement for both types:

:

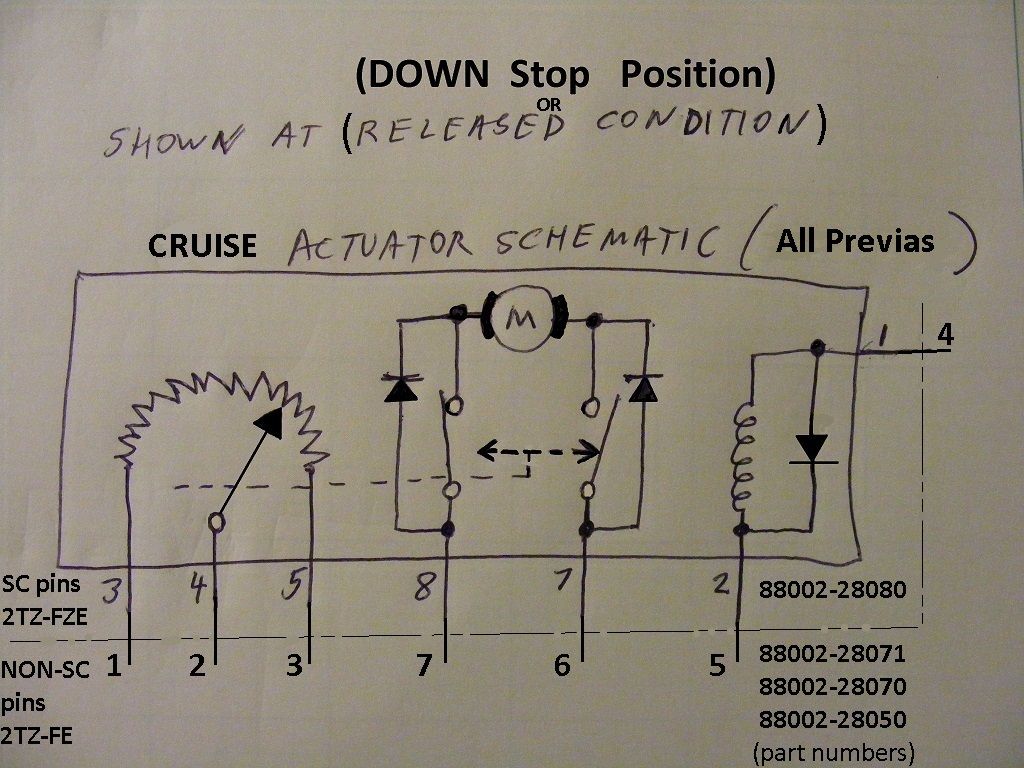

To help understand the actuator’s operation and the values that you will measure, I felt that a better schematic than appears in the Toyota Electrical Schematic would be a good idea. This is how all actuators work, only the pin assignments are different. This schematic shows the correct pin assignments for both types of actuators and illustrates the correct position of the limit switches for the actuator in the off state (which is normally the convention of the Toyota electrical schematics). In the off state (lever released, throttle down),the position sensor is also shown in the schematic as linked to the limit switches and at a relative resistance value indicative of the actual state of the actuator at rest in the car or on the work bench. So the behavior and resistance values measure will make sense, unlike the schematics in the Toyota manuals.

To check the three circuits of the actuator for any obvious failures,, set your ohm meter to the 200 ohms scale.

CLUTCH SOLENOID:

SC: pin 2 to pin 1.

NON-SC: pin 5 to pin 4

Should be aroung 40 ohms. (Book says 39.5, I get 40 and 40.5)

POSITION SENSOR:

Set your ohm meter to the 20 k ohm scale.

SC: pin 3 to pin 5.

NON-SC: pin 1 to pin 3

These are the potentiometer end connections. With the lever arm at throttle down stop (released) Should be around 0.200 kohms (book says 2 kohm. I get 1.960 kohm at room temperature

Set your ohm meter to the 2k ohm scale.

SC: pin 4 to pin 5

NON-SC: pin 2 to pin 3

(pin 4 is the potentiometer wiper connection) with lever arm released, should be around 0.500 kohms. (The book implies about 0.500, I get 0.510 at room temp)

Now test the position sensor center tap contact for wear by continuing to measure the same pins (4 to 5 or 2 to 3 as before) while slowly and smoothly moving the lever arm from one stop to the other and back. The reading should also rise smoothly to around 1.700 kohm and back down smoothly as well without glitching off scale high. (potentiometers sometimes wear out and get “noisy” like the old volume controls in radios). Mine had no problems, but check this anyway serveral times and make sure you have good solid connections to the pins so you don’t get a false reading. Glitching will send erroneous position data to the Cruise ECU. The actual readings are not that critical so expect the bottom resistance to be around 0.500 kohms and the top number to be 1.600 to 1.900 kohms (The book says 0.500 rising to 1.700, mine goes 0.510 to 1.780) The important thing here is no glitching.

MOTOR:

Set the meter to the diode test setting (usually one of the resistance scales has a little diode symbol on it, typically the 2k scale). Polarity here is important or you may not get a proper reading. Testing here may give different readings depending on which scale you use on your ohm meter and which pin the positive lead is on.

SC

ositive red lead on pin 7 and negative black lead on pin 8.

NON-SC: Positive red lead on pin 6 and negative black lead on pin 7

You should get a reading of around 0.900 with the lever arm released. This means that the limit switches are in the proper positions, the motor has continuity thru the brushes, and the diode between the motor and pin 7 is good. What you are reading is the breakdown voltage of that diode with a circuit thru the motor and the “UP” Stop limit switch. That is a silicon diode and will conduct at voltage of around 0.6 to 0.8 volts. The function of the diodes is to conduct power to the motor in one direction only when the lever arm is at one of the stops (one for UP Stop and one for DOWN Stop). The function of the limit switches is to open the circuit and shut off the motor just before it reaches its mechanical limit (stop).

Now move the lever arm off the DOWN Stop to anywhere in mid travel. The resistance should go down to near zero around 0.02 k ohm or less as the DOWN Stop limit switch closes, bypassing the diode. This is the resistance of the motor windings and the two limit switches (mine reads about 0.017 or about 17 ohms on the 2k scale. Continue to move the lever to the UP Stop. The resistance should go off scale high as the UP Stop limit switch opens. If it does, that switch is working perfectly. Complete the test of the motor circuit by reversing the leads.

SC

ositive red lead on pin 8 and negative black lead on pin 7.

NON-SC: Positive red lead on pin 7 and negative black lead on pin 6

With the lever arm all the way to the UP Stop, the value should again be around 0.900 .

All good? This means the three electrical circuits of the Actuator are good. Move on.

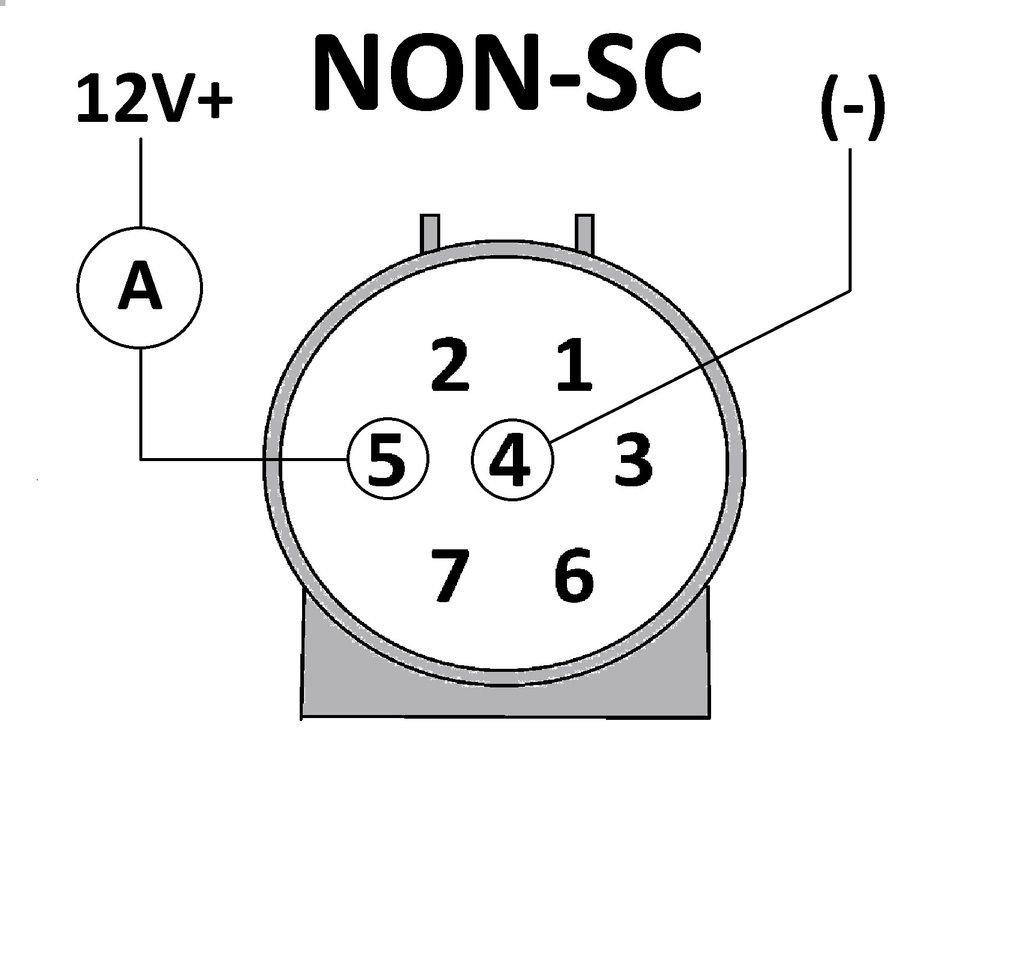

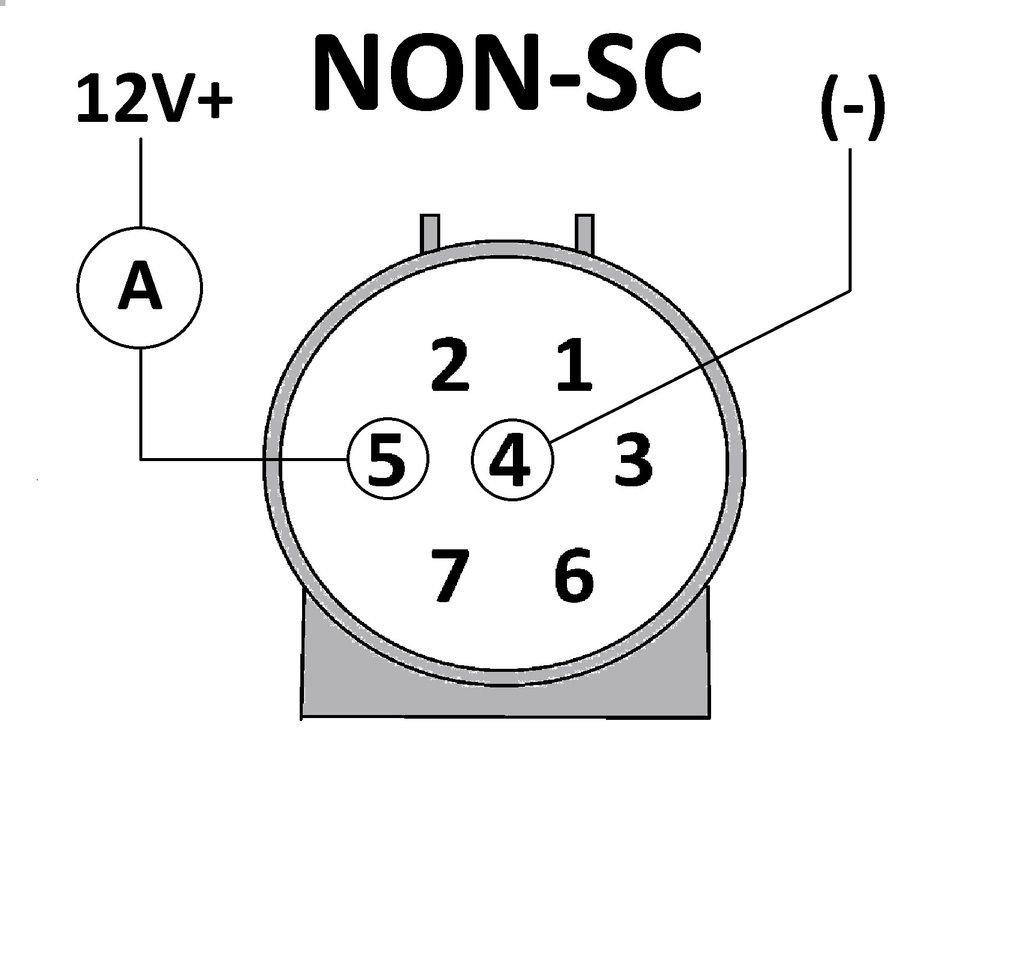

POWER ON TESTS

Continue here only if all tested good with the above tests.

This will test with 12 volt DC power. Using a current limited power supply is safer than using a battery. So if you use a battery be careful not to touch any wrong pins or create a short circuit. Using a 5 amp fuse in one of the battery leads will provide some protection.

You will need a 12v DC power source capable of a couple of amps. If you use a regulated power supply, set the current limit to 2 amps. You can get by with as little as 1 amp. A battery will do, but just remember that an unfused car battery can deliver vaporizing currents to a short or the wrong lead. I made up some test wires with crimp-on type female blade connetors that were small enough and the right size to fit snugly on the pins in the actuator connector. Whatever you use (needles thru the wirs, etc.), just get a good connection that won’t slip off or short something out. I used card stock taped between connector pins to make sure they would not touch each other inside the connector. The best way to test is to make solid connections in the connector, then connect the battery last to do each test.

MAGNETIC CLUTCH TEST:

To test magnetic clutch operation:

SC: 12v positive (red) lead to pin 2 and the negative to pin 1

NON-SC: 12v positive (red) lead to pin 5 and the negative to pin 4

WARNING: connecting backwards may fry the arc suppression diode that is in parallel with this coil.

With power to the magnetic clutch, try to move the Ouput lever arm. It should lock up. The output arm is now engaged with the motor drive train and only the motor will be able to move it. If you are measuring current, it will be about 300 mA (about the same as a typical automotive relay), but measuring it is not needed because the combination of correct resistance and verifying lockup proves it is working properly.

MOTOR TESTING:

I found it easiest to make up another two wires with narrow female connectors on them to hook up the motor. You can use the same battery to power the clutch and the motor, just use two sets of wires. That way you can leave the actuator hooked up and connect the other ends of the wires as needed to the power source without fumbling around in the tight connector and risking a short.If you have a current meter (use the 10A scale and connections), put it in series with the motor as shown. It is convenient to make the final connection at the battery with the current meter so you can glimpse the reading in the short time the motor is running. Also make it so you can change the polarity of the motor (NOT THE CLUTCH) so you can drive the motor back and forth. This test will drive the output lever stop to stop, back and forth. So do not have anything in the lever arm’s way or it will get broken.

Connect the battery to the clutch first as in the Magnetic Clutch Test above (you can leave this connected for hours. It will not hurt anything.

Then hook up the motor wires in the UP drive direction like this.

SC: 12v positive (red) lead to pin 7 and the negative to pin 8

NON-SC: 12v positive (red) lead to pin 6 and the negative to pin 7

When you connect the battery to the motor wires, the lever arm should quietly and smoothly move to the UP Stop at the end of travel in about a second or so. The motor will shut off when the UP Stop limit switch opens.

To drive the lever arm in the DOWN direction, with the clutch still powered, reverse the motor connections at the battery like this:

SC: 12v positive (red) lead to pin 8 and the negative to pin 7

NON-SC: 12v positive (red) lead to pin 7 and the negative to pin 6

The lever arm should smoothly and quietly move to the DOWN Stop position. If at any time you remove power from the clutch, the lever arm should snap back to its starting (DOWN Stop) position. The motor should be able to drive the lever arm only when the clutch is powered. So with the clutch hooked up, drive the lever arm back and forth by swapping the motor connections at the battery as many times as you want to get a feel for how it is operating. Note the highest current reading you can see on the Amp meter while the lever arm is moving. It should be around 0.300 to 0.400 A. The actuators that I have tested with good brushes would draw about 0.330 to 0.350 A You can also power the motor by itself without the clutch and it should free wheel inside the actuator without moving the lever arm. Just hook up the motor in the UP drive direction. It should hum quietly as long as it is powered. One word of CAUTION: When driven like this, the motor will dissipate about 4 watts of powere as long as it is hooked up. This is about the same amount of heat supplied by a 4 watt night light bulb. So I would not leave it on indefinitely, especially if it has worn out brushes. You can also hook up the motor power in the DOWN drive direction, but it will only come on if you also move the lever arm off its DOWN Stop to close the DOWN Stop limit switch. If current you measure is upwards of around 1 amp, the brushes are going. The actuator that I fixed was working some of the time and the motor was drawing about 1.7 amps in this test and was noisy with vibration. Just replacing the brushes fixed it. Good actuators I tested were all well below 1 amp, ran smoothly and were quiet.

Whew!!

I will post the fix next.