Are they the same; Vehicle Skid Control and Vehicle Stability Control?

N.E.O.

My apologizes (I will fix my posts), after further examination here are the facts:

Both terms are used in the shop, however let me clarify. Vehicle Skid Control is used to prevent the vehicle from skiding when coming to a stop by using the abs system. and here is a print out for you on Vehicle Stability Control(which fits the issue of this topic):

(e) VSC (Vehicle Stability Control)

The VSC system helps prevent the vehicle from slipping sideways as a result of strong front or rear wheel skid during cornering.

(1) Operation description

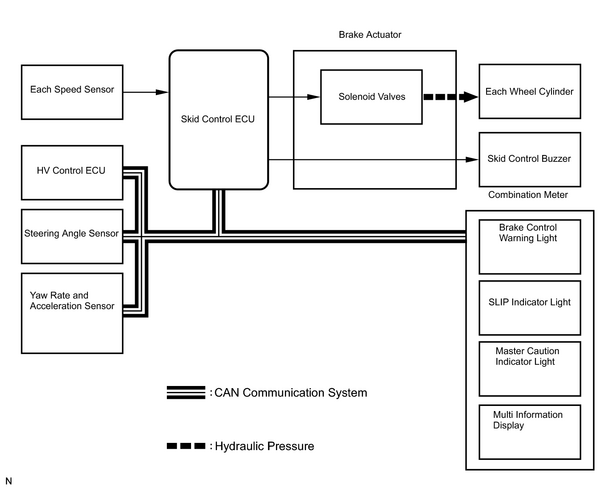

The skid control ECU determines the vehicle operating conditions based on signals received from the wheel speed sensors, yaw rate and acceleration sensor, and steering angle sensor. The skid control ECU sends signals via CAN communication to the HV control ECU in order to control engine torque. The skid control ECU controls brake hydraulic pressure using the solenoid valves.

The SLIP indicator light will blink, and the skid control buzzer will sound when the system is operating. If a malfunction occurs in the VSC system, both the brake control warning, master caution indicator and the SLIP indicator lights will come on. In addition, the DTC will appear on the multi information display.

Here are some interesting notes for you!

FUNCTION OF COMPONENTS-

Skid control ECU:

Processes the signals from each sensor to perform brake control for ABS, TRAC, and VSC. In addition, it communicates with the HV control ECU to output a control signal.

ABS main relay (ABS NO. 1, 2 relay):

Controlled by the skid control ECU. In addition to supplying power to each solenoid, it supplies power to the skid control ECU.

ABS motor relay (ABS MTR1, 2 relay):

Controlled by the skid control ECU. Supplies power to the pump motor.

Speed sensor:

Detects the wheel speed and inputs the results to the skid control ECU.

Stop light switch:

Detects the brake operating conditions and inputs the results to the skid control ECU. It supplies power to the skid control ECU.

Brake pedal stroke sensor:

Detects the brake pedal stroke volume and inputs the results to the skid control ECU.

Brake control power supply:

Provides the system with a supplementary power supply by discharging the electric charge of the capacitor. It happens when an electric charge is accumulated in the capacitor in the unit and the vehicle power voltage (12 V) is reduced.

Skid control buzzer:

- Sounds intermittently to inform the driver that the VSC is active.

- Sounds continuously to warn the driver of a reduction in accumulator hydraulic pressure in the brake actuator, an abnormality in the power supply system, or a reduction in the vehicle power voltage (12 V).

HV control ECU:

Controls the engine output during the operation of TRAC and VSC by communicating with the skid control ECU.

Yaw rate and acceleration sensor:

Detects the yaw rate (axial rotation) and the forward, rearward and lateral acceleration, and inputs the results to the skid control ECU.

Steering angle sensor:

Detects the steering angle and direction, and outputs the results to the skid control ECU through CAN communication.

Master cylinder:

Generates pressure in accordance with the force of the brake operation.

Brake fluid reservoir:

Stores brake fluid for the master cylinder system and power supply system.

Brake fluid level warning switch:

Detects a reduction in the level of the brake fluid in the reservoir.

Stroke simulator:

Generates a natural pedal stroke in accordance with the pedal force of the driver during system operation (integrated with the master cylinder).

Stroke simulator cut valve (SCSS):

Sends brake fluid pressure generated in master cylinder to stroke simulator during system control.

Brake actuator:

Controls the hydraulic pressure of each of the four wheel cylinders using the output signal of the skid control ECU.

Pump motor:

Pumps up the brake fluid from the reservoir and supplies the accumulator with high hydraulic pressure.

Accumulator:

Accumulates for the hydraulic pressure that was generated by the pump.

Accumulator pressure sensor (PACC):

Built into the brake actuator to detect the accumulator hydraulic pressure.

Relief valve:

Prevents excessive high pressure in the power supply system. It relieves the system by sending brake fluid to the reservoir when the pump has operated continuously, for example, during an accumulator hydraulic pressure sensor malfunction.

Master cylinder pressure sensor:

(PMC1, PMC2)

Built into the brake actuator to detect the pressure of the master cylinder and input the results to the skid control ECU.

Wheel cylinder pressure sensor:

(PFR, PFL, PRR, PRL)

Built into the brake actuator to detect the brake hydraulic pressure of each wheel cylinder.

Switching solenoid valve:

(SMC1, SMC2)

Switches the brake hydraulic pressure route according to whether normal brakes are used, or VDIM (ABS, TRAC and VSC) control is used.

Linear solenoid valve:

(SLA##, SLR##)

Controls the wheel cylinder hydraulic pressure during normal brake operation, and VDIM (ABS, TRAC and VSC) control. SLA## are solenoids for controlling pressure increases, while SLR## are solenoids for controlling pressure decreases.

ABS warning light:

- Comes on to inform the driver that a malfunction in the ABS or BA has occurred.

- Blinks to output DTC.

BRAKE warning light:

Comes on to inform the driver that the parking brake is on when the system is normal or the brake fluid has decreased.

Brake control warning light:

Comes on to inform the driver that a malfunction in the Electronically Controlled Brake or VSC system has occurred.

SLIP indicator light:

Blinks to inform the driver that TRAC and VSC are operating.

Master caution indicator light:

Comes on to inform the driver that a malfunction in the Electronically Controlled Brake or VSC system has occurred.

Multi information display:

- Displays to inform the driver that a malfunction in the Electronically Controlled Brake or VSC system has occurred.

- Displays output DTC.