Ok guys for those that want to build there motor to handle boost , i will post everything that needs to be done to have a good built forged motor. this is my build.

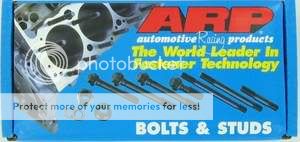

1. things you need .

arp rod , main and head bolts - 4agze motor

![Image]()

Cp pistons 4agze rods and ze crank

note: you can not use the crank or rods off the 4ag. on the 7afe only the pistons can be used.

go to Belfab Racing.com they have 7afe forged rods. you will have to use the stock crank.

![Image]()

you can see the two 4afe next to 4agze rod.

![Image]()

time to put the pistons and rods togeather.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Now dropping in the crank and bolt down the main bolts , arp 60 foot lbs

![Image]()

![Image]()

![Image]()

![Image]()

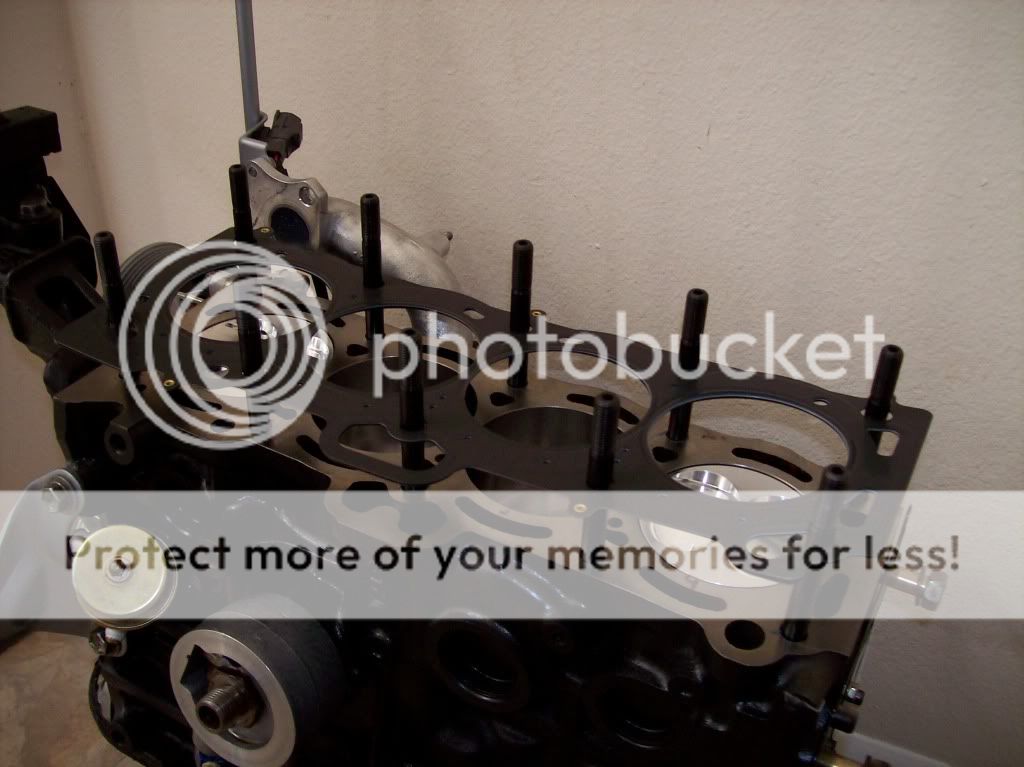

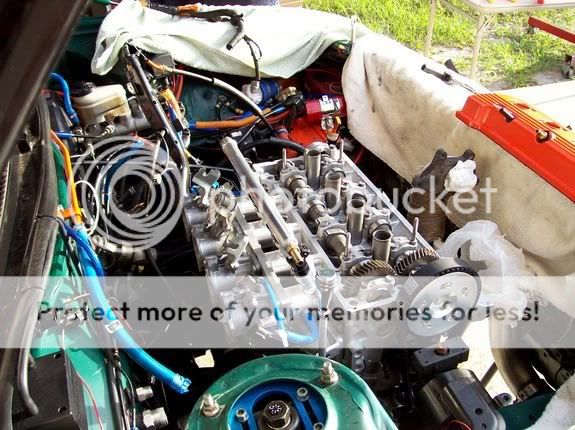

Time for the Head

Note : you can use 4age valves the intake are the same size round but the exhaust are a little bigger , take it to the machine shop to have it worked out.

![Image]()

![Image]()

i am using 4agze exhaust valves , because they are bibber fastair coming in and fast coming out.

![Image]()

Time to drop the pistons in.

Note : Make shore the rings are gapped right for your style

![Image]()

![Image]()

![Image]()

Torque down the rod bults to 40 foot lbs.

turn the crank to do the next set.

![Image]()

1. things you need .

arp rod , main and head bolts - 4agze motor

Cp pistons 4agze rods and ze crank

note: you can not use the crank or rods off the 4ag. on the 7afe only the pistons can be used.

go to Belfab Racing.com they have 7afe forged rods. you will have to use the stock crank.

you can see the two 4afe next to 4agze rod.

time to put the pistons and rods togeather.

Now dropping in the crank and bolt down the main bolts , arp 60 foot lbs

Time for the Head

Note : you can use 4age valves the intake are the same size round but the exhaust are a little bigger , take it to the machine shop to have it worked out.

i am using 4agze exhaust valves , because they are bibber fastair coming in and fast coming out.

Time to drop the pistons in.

Note : Make shore the rings are gapped right for your style

Torque down the rod bults to 40 foot lbs.

turn the crank to do the next set.