Background:

Pre-Ignition, Detonation, Knocking, Pinging along with Dirty, Grimy, Ass-tastic carbon deposits. (which heat up tremendously and also cause pre-ignition) It's hard to put together two things that will hamper performance, and destroy a running engine in a shorter span of time!

There must be a way to easily defeat them both, without compromising performance, and reliability.

Theory:

Enter water & water/alcohol injection! We'll skip technical detail for a short list.

Water injection suppresses detonation like no other. It accomplishes this in three basic ways:

1) The incoming air charger is significantly cooled by the atomized water

2) Combustion chamber temperature, if a larger amount of water is injected, are lowered.

3) The water cleans off carbon in the intake track, while the steam created in the combustion chambers blasts carbon off parts clear into some of the exhaust manifold.

Because of this, depending on the amount of water / mixture injected, the octane rating of the fuel is effectively raised 15-30 points!

How much water is needed? Well. That is a loaded question. Typically, you add your mixture, which is now both fuel AND WATER and take 12-25% of that.

Water/alcohol injection.

Short and sweet! Adding up to a 50% alcohol ratio to the water will increase it's charge cooling efficiency. We do *NOT* NOT NOT NOT want to injection alcohol as an extra "fuel". IT DOES NOT WORK THIS WAY!!!

There are three types of alcohol you can inject: Methyl, Ethyl, and Isopropyl.

Isopropyl (rubbing alcohol) CAN NOT BE USED!!! It *will* try to burn during the combustion process and suck a significant amount of oxygen from the gasoline.

Both Methyl and Ethyl WILL NOT burn in a majority gas combustion process... It's next to impossible as they are under their lower explosive limit (the ratio of air to fuel needed to combust). Isopropyl WILL try to burn, as it is just above it's lowest explosive limit. That causes the mixture to be extremely rich.

That leaves us with methyl, or ethyl alcohol. Throw out methyl! It eats Aluminum over time!!! That leaves us with regular ethyl alcohol. It can be bought in paint stores for $10 a gallon.

Instructions:

Sadly, you can't just go out and buy fuel injection parts. Water conducts electricity, and the Alcohol will eat away at gasoline safe parts. You would corrode a fuel injector shut rather shortly. Noone wants to rebuild an injector every month :\.

Thankfully! Toyota has given us a gasoline injector that *CAN* tolerate water! The old style Cold-Start Injectors!!! They consist of nothing more than an atomizer, and a solenoid to open/close the injector.

Now we have two upsides, and a downside. On the good side, unlike just buying an atomizer nozzle, when the injector is turned off, boost will NOT flow down the injector/water will NOT be sucked out by vacuum. This is a simple injector, NO DRIVING equipment is needed!!! That's also the bad news, being a simple injector, it's either on, or off with nothing in between. If you don't like it, you can simply cut the shaft off and use it's atomizer.

What does a used cold-start injector cost??? Try $1.50 on ebay. Less than $5 shipped! (2vz-fe / 3vz-fe CSI's are fine. The 2vz-fe injetor is 1 1 /2" longer, so I would take a 3vz-fe injector before that as it would have an easier time fitting in the middle of the intake.

The flow rate for a clean injector is around 150cc/min (OF GAS, NOT WATER) at 30psi.

What do we do for a water supply? Seeing how engine bay space is at a premium, and we all-ready have a 5 quart water supply installed; al-la washer tank. That's the supply!

Water pump. originally I bought a windshield washer pump. (again, used Toyota part shipped for less than $5 on ebay) Unfortunately, this does not deliver enough flow for a boosted setup on it's own. I couldn't use it. I am sure if you bumped it's voltage up to 18-24v it would be a *perfect* pump to use!

So... I was forced to drop a spare gas pump I have laying around! All 80lph of it. It's hard to find information either way about submerging a fuel pump in water, and pumping it. Then again it's a spare so I don't care what happens.

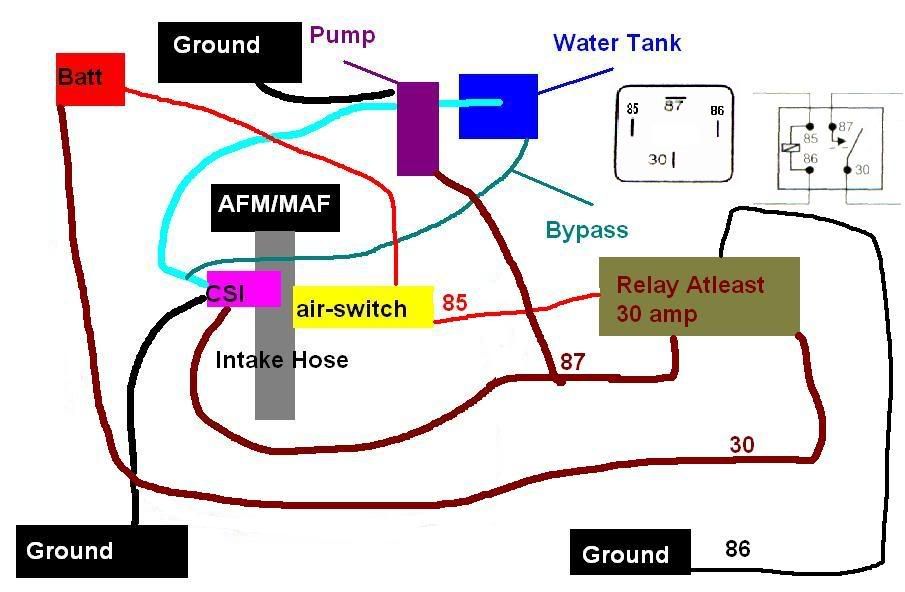

I have simply hooked both the pump, and injector up to a 40 amp relay (again, bought on ebay for $2.50, shipped for $4). Which is triggered by the switchable ground on my SMT-6. This way I can trigger it by any combination of the following: Throttle position, RPM, A 0-5v source, another 5v source. (such as, a map/boost sensor, and temperature sensor)

For anyone *not* using an SMT, you could do something like using a boost switch. They're typically found in 1-4psi, 5-14psi, 14psi+ versions for $15-$25 new. This isn't the best way to do this as the water would be trigger many times in normal driving when it shouldn't.

Originally, the flow was simply insane! The water pressure in the line must have been phenomenal as the 150cc (gasoline) CSI was flowing somewhere around 600cc/m !? That's the flow you would want around 450-550hp on a boosted engine!!! It could empty a one gallon milk jug in just over 4 min!

Something had to be done! I used a smaller line to restrict water flow, and a smaller line to restrict water intake. Now we're down around 450cc/m as It takes just over 60 seconds to empty a 20oz coke bottle!

Eventually, I will wire a large potentiometer to lower the output further at a later time.

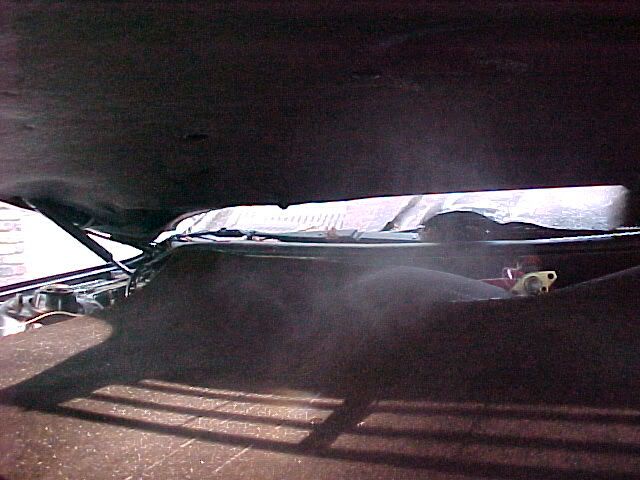

This particular digi-cam has a hard time picking out the water, since it's installed, I can't take it out and put it against a bright backlight on a black background. So we'll make do!

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

****************************************

One other thing worth mentioning... When you're on boost running water injection, you have no reason to fuel past your peak power. (typically 12.5) The water is doing all the leg work of cooling the charge, and much better at controlling the pre-ignition in the combustion chamber than vaporizing gas is!

****************************************

****************************************

Other Articles in the Series:

Part I Quicker Transmission Shifting

Part II Adding Airflow

Part III Taking Advantage of Intake/Exhaust Upgrades

Part IV Cheaply Monitoring the ECU & A/F

Part V How to pick up MPG, and sleep with her too!

Part VI Acing Aerodynamics

Part VII Cheap Water Injection

Part VIII Electronic Transmission Controller

****************************************

Pre-Ignition, Detonation, Knocking, Pinging along with Dirty, Grimy, Ass-tastic carbon deposits. (which heat up tremendously and also cause pre-ignition) It's hard to put together two things that will hamper performance, and destroy a running engine in a shorter span of time!

There must be a way to easily defeat them both, without compromising performance, and reliability.

Theory:

Enter water & water/alcohol injection! We'll skip technical detail for a short list.

Water injection suppresses detonation like no other. It accomplishes this in three basic ways:

1) The incoming air charger is significantly cooled by the atomized water

2) Combustion chamber temperature, if a larger amount of water is injected, are lowered.

3) The water cleans off carbon in the intake track, while the steam created in the combustion chambers blasts carbon off parts clear into some of the exhaust manifold.

Because of this, depending on the amount of water / mixture injected, the octane rating of the fuel is effectively raised 15-30 points!

How much water is needed? Well. That is a loaded question. Typically, you add your mixture, which is now both fuel AND WATER and take 12-25% of that.

Water/alcohol injection.

Short and sweet! Adding up to a 50% alcohol ratio to the water will increase it's charge cooling efficiency. We do *NOT* NOT NOT NOT want to injection alcohol as an extra "fuel". IT DOES NOT WORK THIS WAY!!!

There are three types of alcohol you can inject: Methyl, Ethyl, and Isopropyl.

Isopropyl (rubbing alcohol) CAN NOT BE USED!!! It *will* try to burn during the combustion process and suck a significant amount of oxygen from the gasoline.

Both Methyl and Ethyl WILL NOT burn in a majority gas combustion process... It's next to impossible as they are under their lower explosive limit (the ratio of air to fuel needed to combust). Isopropyl WILL try to burn, as it is just above it's lowest explosive limit. That causes the mixture to be extremely rich.

That leaves us with methyl, or ethyl alcohol. Throw out methyl! It eats Aluminum over time!!! That leaves us with regular ethyl alcohol. It can be bought in paint stores for $10 a gallon.

Instructions:

Sadly, you can't just go out and buy fuel injection parts. Water conducts electricity, and the Alcohol will eat away at gasoline safe parts. You would corrode a fuel injector shut rather shortly. Noone wants to rebuild an injector every month :\.

Thankfully! Toyota has given us a gasoline injector that *CAN* tolerate water! The old style Cold-Start Injectors!!! They consist of nothing more than an atomizer, and a solenoid to open/close the injector.

Now we have two upsides, and a downside. On the good side, unlike just buying an atomizer nozzle, when the injector is turned off, boost will NOT flow down the injector/water will NOT be sucked out by vacuum. This is a simple injector, NO DRIVING equipment is needed!!! That's also the bad news, being a simple injector, it's either on, or off with nothing in between. If you don't like it, you can simply cut the shaft off and use it's atomizer.

What does a used cold-start injector cost??? Try $1.50 on ebay. Less than $5 shipped! (2vz-fe / 3vz-fe CSI's are fine. The 2vz-fe injetor is 1 1 /2" longer, so I would take a 3vz-fe injector before that as it would have an easier time fitting in the middle of the intake.

The flow rate for a clean injector is around 150cc/min (OF GAS, NOT WATER) at 30psi.

What do we do for a water supply? Seeing how engine bay space is at a premium, and we all-ready have a 5 quart water supply installed; al-la washer tank. That's the supply!

Water pump. originally I bought a windshield washer pump. (again, used Toyota part shipped for less than $5 on ebay) Unfortunately, this does not deliver enough flow for a boosted setup on it's own. I couldn't use it. I am sure if you bumped it's voltage up to 18-24v it would be a *perfect* pump to use!

So... I was forced to drop a spare gas pump I have laying around! All 80lph of it. It's hard to find information either way about submerging a fuel pump in water, and pumping it. Then again it's a spare so I don't care what happens.

I have simply hooked both the pump, and injector up to a 40 amp relay (again, bought on ebay for $2.50, shipped for $4). Which is triggered by the switchable ground on my SMT-6. This way I can trigger it by any combination of the following: Throttle position, RPM, A 0-5v source, another 5v source. (such as, a map/boost sensor, and temperature sensor)

For anyone *not* using an SMT, you could do something like using a boost switch. They're typically found in 1-4psi, 5-14psi, 14psi+ versions for $15-$25 new. This isn't the best way to do this as the water would be trigger many times in normal driving when it shouldn't.

Originally, the flow was simply insane! The water pressure in the line must have been phenomenal as the 150cc (gasoline) CSI was flowing somewhere around 600cc/m !? That's the flow you would want around 450-550hp on a boosted engine!!! It could empty a one gallon milk jug in just over 4 min!

Something had to be done! I used a smaller line to restrict water flow, and a smaller line to restrict water intake. Now we're down around 450cc/m as It takes just over 60 seconds to empty a 20oz coke bottle!

Eventually, I will wire a large potentiometer to lower the output further at a later time.

This particular digi-cam has a hard time picking out the water, since it's installed, I can't take it out and put it against a bright backlight on a black background. So we'll make do!

****************************************

One other thing worth mentioning... When you're on boost running water injection, you have no reason to fuel past your peak power. (typically 12.5) The water is doing all the leg work of cooling the charge, and much better at controlling the pre-ignition in the combustion chamber than vaporizing gas is!

****************************************

****************************************

Other Articles in the Series:

Part I Quicker Transmission Shifting

Part II Adding Airflow

Part III Taking Advantage of Intake/Exhaust Upgrades

Part IV Cheaply Monitoring the ECU & A/F

Part V How to pick up MPG, and sleep with her too!

Part VI Acing Aerodynamics

Part VII Cheap Water Injection

Part VIII Electronic Transmission Controller

****************************************