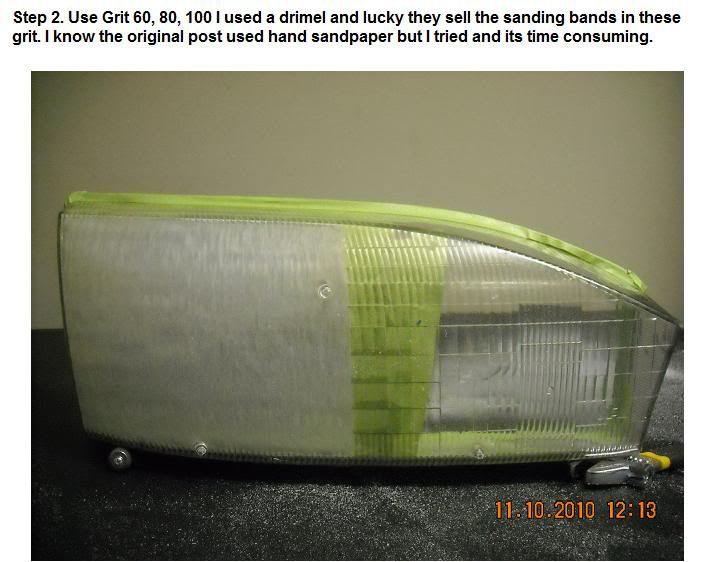

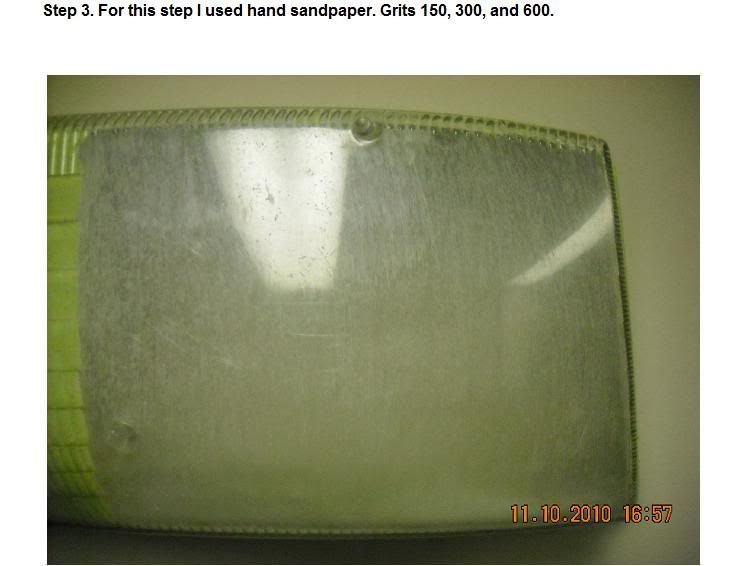

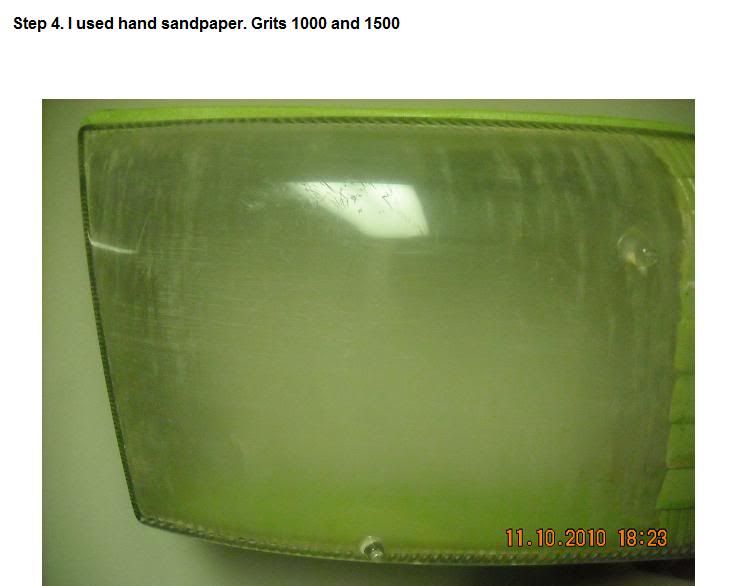

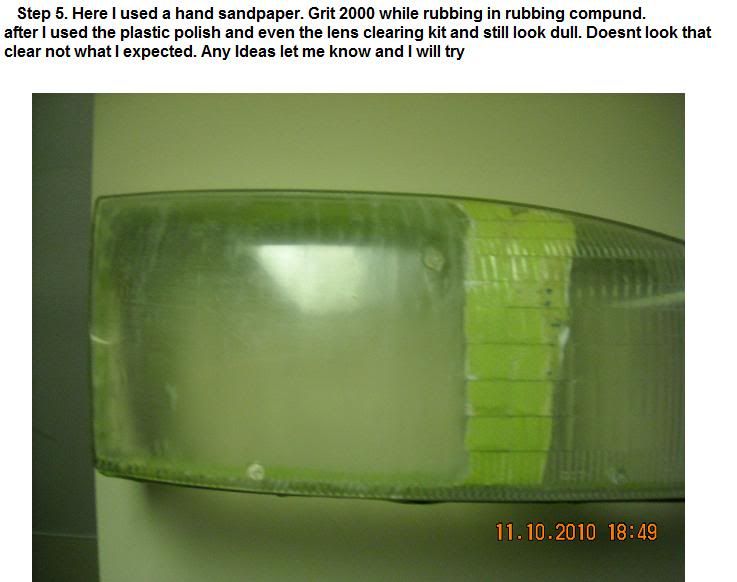

Now being that I work from home and get bored alot I decided to make an attempt of making some clear headlight. But not easy at all and feel like Im missing something from making them look better then there now any help from anyone please.

And I followed the grit sizes. From the ORIGINAL DYI.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

And I followed the grit sizes. From the ORIGINAL DYI.